Other Parts

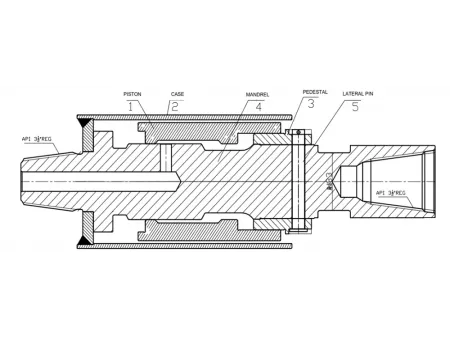

Back hammer

The back hammer is designed to assist in pulling out the drill string. During stuck-hole or collapsed-hole operations, it can significantly reduce downtime and operational costs, improving overall drilling efficiency.

| Model | Air pressure, bar | Connection thread | Diameter, mm | Weight, kg |

| 6'' back hammer | 8-15 | API 3 1/2'' REG | 192 | 71.5 |

| 10'' back hammer | 8-15 | API 3 1/2'' REG | 273 | 130.5 |

| 14'' back hammer | 8-15 | API 5 1/2” REG | 325 | 201 |

Other specifications are available upon request.

Breakout bench

A fully automatic hydraulic breakout bench designed for easy and efficient disassembly of drilling tools. The bench is user-friendly, fast to operate, and suitable for high-frequency on-site operations.

| Model | Dimensions (L x W x H), mm | Hydraulic tank capacity, L | Weight, kg |

| 3''-6'' breakout bench | 820x850x1000 | 40 | 400 |

| 6''-8'' breakout bench | 1320x920x920 | 70 | 690 |

| 8''-12'' breakout bench | 1400x1140x1180 | 70 | 820 |

Shock Absorber

- Effectively absorbs reverse impact forces generated by the DTH hammer, protecting the drill rig power head, especially critical in large-diameter drilling applications.

- Available in two structural designs: Threaded type for water well drilling, oil & gas, shale gas, and geothermal applications; Hexagonal type primarily used in large-diameter foundation piling projects.

- Compatible with DTH drilling rigs, water well rigs, piling rigs, rotary drilling rigs, and related equipment.

| Model | Max. buffer stroke, mm | Elastic component | Connection thread | Dimensions (Ø x L), mm | Weight, kg |

| 6'' absorber | 25 | PU washer | API 3 1/2'' REG | 182 x 565 | 100 |

| 12'' absorber | 75 | Disc spring | API 6 5/8'' REG | 273 x 885 | 300 |

| 18'' absorber | 125 | Disc spring | Hexagonal 273 | 278 x 1400 | 345 |

Tube drawing Bench

A compact and lightweight device specifically designed for casing extraction. Its narrow structure allows operation in confined or limited-access sites, making it ideal for small pits and restricted job sites.

| Model | Lifting force, kN | Pressure, MPa | Input power | Applicable casing tube O.D., mm |

| 50T | 492 | 20 | 380V, 50Hz | Max.178 |

| 70T | 616 | 20 | 380V, 50Hz | Max.194 |

| 100T | 1016 | 20 | 380V, 50Hz | Max.219 |

| 150T | 1256 | 20 | 380V, 50Hz | Max.273 |

| 200T | 1960 | 20 | 380V, 50Hz | Max.325 |

All drilling systems are supported with high-stability air compressors, quick-release auxiliary tools, and intelligent lubrication systems, significantly improving maintenance efficiency and ensuring uninterrupted round-the-clock operation.

Both mobile and modular air compressors support working pressures from 8 to 34 bar, equipped with large-capacity filtration systems, automatic condensate discharge, and thermal control modules, ensuring long-term stable operation across diverse and harsh environments.

A complete range of casing pullers, breakout benches, three-jaw chucks, power-head adapters, and other accessories is available. All auxiliary tools are designed for quick installation and removal, significantly improving on-site assembly, disassembly, and maintenance efficiency.

Leveraging many years of global field experience to provide perfectly matched drilling tools, drill rigs, and air compressors for your toughest projects.