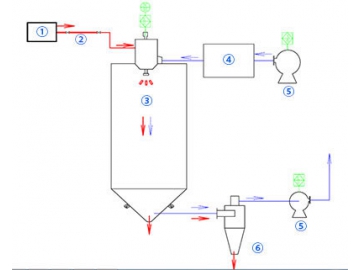

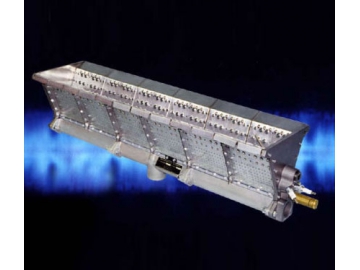

Spray Dryer with PSD Drying System

Description

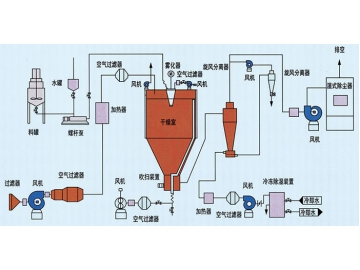

The spray dryer with PSD drying system is mainly used for material drying such as traditional Chinese medicine, chemical products and some other materials featuring bad heat sensitivity, bad drying performance, low softening point, strong moisture absorption.

This dryer adopts high speed centrifugal atomizer to disperse the material into fog, so that the material can fully contact with hot air. Thus the material will be dried instantly and you will get powder products.

Main application

Food drying

Sugar drying

Medical products drying

Chemical product drying etc.

| Type | PSD-12 | PSD-20 | PSD-25 | PSD-30 | PSD-35 | PSD-40 | PSD-45 | PSD-50 | PSD-55 | |

| Water evaporation quantity(kg/h) | 1-5 | 8-10 | 10-20 | 30-40 | 50-80 | 80-100 | 100-150 | 120-200 | 150-250 | |

| Material treating quantity(kg/h) | 3-5 | 10-20 | 20-30 | 30-80 | 50-120 | 80-150 | 120-200 | 160-280 | 220-380 | |

| Solid content of wet material(%) | 15-30 | |||||||||

| Finished product water content(%) | 3-5 | |||||||||

| Electric power(KW) | 21 | 36 | 45 | 63 | 126 | 180 | 216 | 270 | 360 | |

| Heating source | Steam (0.6~0.8MPa)+electricity | |||||||||

| Product collection method | Cyclone separator+wet dust collector | |||||||||

| Project control system | Project control system or human-computer interface PLC control; adopting Fuzzy technology to track exhaust temperature to realize variable air temperature to match material feeding quantity. | |||||||||

| Inlet air temperature(℃ ) | 120~220 | |||||||||

| Outlet air temperature(℃ ) | 80~100 | |||||||||

| Diameter of the drying room(mm) | 1200 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | |

| Outline dimension | L | 2500 | 3600 | 5000 | 6000 | 7500 | 8000 | 9000 | 10000 | 12000 |

| Outline dimension | W | 1800 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 |

| Outline dimension | H | 3000 | 5000 | 5800 | 7000 | 7500 | 8500 | 9000 | 10000 | 11500 |

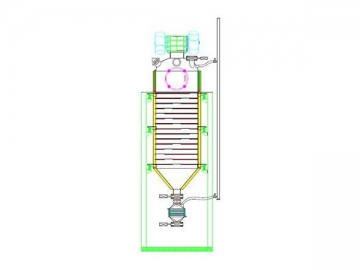

- The spray dryer with PSD drying system adopts fully enclosed appearance. All parts are made of stainless steel. This dryer is equipped with 3-stage purification plant. The filtering finished air can meet 100K cleanliness standard.

- The dryer tower is equipped with wall cooling device so that the wall temperature can be <80℃. So there will be no material coking when the material is resting on the wall. The powder collection rate can be up to 95% without phenomenon of material mixing and sticking on the wall.

Main components

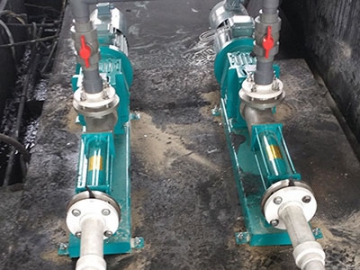

- Material feeding pump

NETZSCH screw pump imported from Germany

NETZSCH screw pump imported from Germany - Atomizer

rotary atomizer

rotary atomizer  Centrifugal atomizing disc of various specifications

Centrifugal atomizing disc of various specifications

Air distributor: it is installed at the top of the tower so that it can be used to control the air flow of inside the drying tower.

Air heating system: it can be used to provide hot air for drying. The heating system can adopt petroleum, natural gas, steam or electrical heating system.

Direct-fired combustor control assembly

Direct-fired combustor control assembly Direct-fired combustor nozzle

Direct-fired combustor nozzle

Drying tower: cylindrical tower which is equipped with a fluid bed at the cone bottom.

Exhaust system:

Cloth bag filter

Cloth bag filter Powder processing device

Powder processing device

Besides drying equipment for pharmaceutical industry, JiangSu Xiandao can provide more kinds of drying equipment or granulating machinery. Besides the dryers, we can also provide related supporting services such as design, installation, maintenance, equipment update etc. If you want to learn more information, please contact us, we will try our best to solve the problem you encountered in production.