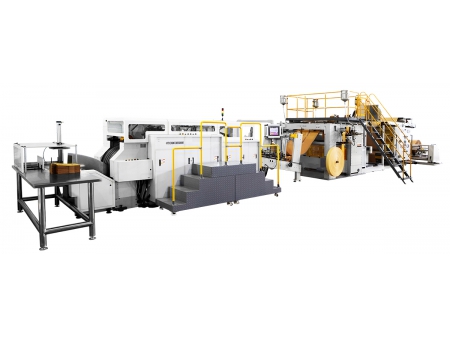

FSB1600 Full-SERVO Flat & Satchel Paper Bag Machine

The FSB1600 full-servo flat & satchel paper bag machine is a coned-bottom paper processing equipment that combines international advanced technology with market demands both at home and abroad. This machine is fully capable of gelatinizing and patching on original color or printed roll paper simultaneously with the use of one machine, as well as applying side glue, draw rolls, cutoff, gelatinizing at bottom, shaping bag, and count collection. The construction of the whole machine is reasonable, compact, and the machine itself is easy to adjust, with its control being a high speed CPU and touch screen display. With a servo motor controlling the bag production speed, it can produce bags with a single channel or dual channel (producing two bags at one time), with a maximum speed as high as 1000PCS/min. It is an ideal choice in replacing imported equipment.

| Technical Info | | | |

| Single Stream | Face Width (w/o Gusset) (mm) | 80-320 | 39-368 |

| Face Width (with Gusset) (mm) | / | 51-317 | |

| Total Gusset (mm) | / | 13-127 | |

| Dual Stream | Face Width (w/o Gusset) (mm) | / | 39-177 |

| Face Width (with Gusset) (mm) | / | 51-146 | |

| Total Gusset (mm) | / | 13-76 | |

| Bag Length (mm) | 140-645 | / | |

| Gusset Size (mm) | 25-100 | / | |

| Cutoff Length Range (mm) | 145-650 | 102-292 | |

| Maximum Web Width (mm) | 910 | 762 | |

| Maximum Roll Diameter (mm) | Φ1500 | Φ1200 | |

| Paper Substrate Range (gsm) | 30-70 | 30-65 | |

| Plastic Window Width (mm) | 50-200 | / | |

| Minimum Seam Overlay (mm) | 20 | 16 | |

| Minimum Former Flap = Seam Overlay Seam Offset (mm) | 25 | 25 | |

| Max. Speed | One Stream (bags/min) | 550 | 800 |

| Double Stream (bags/min) | / | 1600 | |

| Total Power (kW) | 19.65 | 19.65 | |

| Weight (kg) | 5500 | 4500 | |

| Machine Size (L×W×H)(m) | 8.5×3×1.96 | 7.5×3×1.96 | |

| Options Unit |

| ||

- This paper bag forming machine is equipped with a Japanese Mitsubishi servo system and SICK photocell for correction and accurate tracking of the printed material. This minimizes the adjustments and pre-set times.

- Equipped with Mitsubishi electric control system and Mitsubishi motion controller (CPU), as well as the use of an optical fiber, this machine achieves a high speed and high precision motion control and production flow test. With a touch screen display, the operation functions are clear, allowing for a great human to machine interface.

- Equipped with an Italian Re Tension System, and German BST WEB guiding system, production costs are lower and efficiency is improved.

- The paper bag machine is equipped with an American NORDSON cold spray adhesive system for bag side seal, ensuring a high-speed production. (TWO LINES).

- Center web slitting for dual stream production, and Sunhope Weber rotary cutoff knives.

- An enclosed USA Cole-Parmer primary gear runs in oil which is circulated using a pump.

- Bags are delivered vertically (on end) with a programmable counter to adjust bag count.

* Not all face width to gusset combinations can be run on this machine. Please consult SUNHOPE personnel for specific combinations.

** Face widths on dual stream are also affected by the width of the seam overlay and its position on the bag. Please consult SUNHOPE personnel for specific combinations.