Lacquering Oven

Description

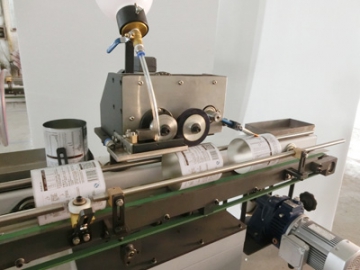

The GHC02 gas fired lacquer curing oven for aluminum cans is the supplementary equipment in the automatic aluminum can manufacturing plant and is charged with the curing effect of the inner coating after the inner wall spray. The curing oven is equipped with the independent motor so that it can not only remain synchronous operation with the equipment next to it but also operate independently. The cylindrical shapes after spraying are transmitted into the stainless C shape chain of the curing oven by the conveyor chain. Because of the carrying of the chain, the cylindrical shapes follow the C shape chain and cycle to the outlet. The C shape chain pours out the cylindrical shapes which have had the high temperature baking and fall into the output chain. The cylindrical shapes have been heated with high temperature for some time inside the curing oven so that the inner spraying fluid attached on the inner wall of the cans are seasoned and attached on the inner wall firmly. That's how the whole curing process is finished.

| Aluminum can diameter | Φ35~Φ66mm |

| Maximum applicable can length | 270m |

| Production speed | 80~120/min |

| Power/temperature | 7KW/200~280℃ |

| Dimensions | 11000*1800*3980mm |

| Total weight | About 13500Kg |

- The curing oven adopts PLC control and automatic temperature control. SCIO fuel burner can adjust the fire automatically according to the temperature changes inside the oven. FUJI temperature controller guarantees that the temperature is within ±2℃ of the standard temperature.

- After the heat inside the combustion chamber finishes the het exchange through the heat exchanger, the fan sends the hot air to the curing zone. The hot air continually cycles inside the oven after the cyclic transport. The temperature inside the oven is even and the products have high quality.

- The curing machine can use not only natural gas but also liquefied petroleum gas. Using gas to offer heat is low-cost and can warm up quickly.

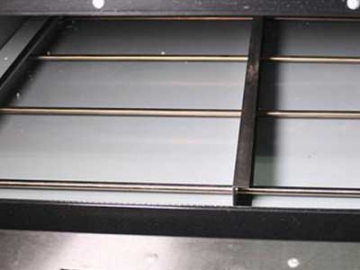

- The furnace cavity adopts hanging structure which can be convenient for maintaining and can make the conveyor chain operate more smoothly and reduce the problems of can falling and can crushing so that the pass rate of the products is improved.

Furnace cavity

Furnace cavity  Motor

Motor  Combustion controller

Combustion controller