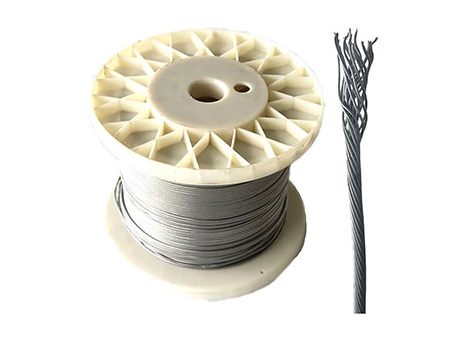

Nickel-Chromium Stranded Resistance Heating Wire

Heat treatment processes often require consistent and accurate performance from resistance wires. To meet these demands, OHMALLOY closely collaborated with cable manufacturers to develop high-quality stranded resistance wires, including FeCrAl, NiCr, NiMn, and pure nickel varieties. These wires are designed to deliver stable electrical resistance and exceptional durability in challenging thermal conditions.

Nickel-chromium wire is known for its high resistivity, excellent oxidation resistance, and ability to withstand elevated temperatures. It also maintains good mechanical strength and weldability, making it suitable for various industrial heating applications.

Specifications| Alloy | Nominal composition % | Resistivity | Max Temp | |||||

| Ni | Cr | Fe | Al | Mn | (Ωmm2/m) | ℃ | ||

| NiCr80/20 | 80 | 20 | 1.09 | 1200 | ||||

| NiCr60/15 | 60 | 16 | Bal | 1.11 | 1150 | |||

| OCr23Al5 | 22 | Bal | 4.8 | 1.35 | 1300 | |||

| OCr20Al5 | 22 | Bal | 5.3 | 1.39 | 1300 | |||

| Pure Nickel | 99.6 | 0.09 | ||||||

| NiMn2 | 98 | 2 | 0.11 | |||||

| Alloy | Nominal OD | N° of strands | Strand diameter | Electrical resistance | Length | |

| mm | mm | Ω/m | m/kg | |||

| NiCr80/20 | 2.7 | 19*0.523 | 0.574 | 0.285 | 29 | |

| NiCr60/15 | 2.76 | 19*0.523 | 0.574 | 0.29 | 30 | |

| NiCr80/20 | 2.76 | 37*0.385 | 0.45 | 0.279 | 28 | |

| Nickel | 2.87 | 19*0.574 | 0.574 | 0.0198 | 21 | |

| NiMn2 | 2.87 | 19*0.574 | 0.71 | 0.0234 | 22 |

Stranded resistance heating wire is suitable for use in ceramic pad heater components, such as:

- Heating Wire

- Ceramic Bead

- Male&female connector