AC Resistance Spot Welding Machine

AC resistance spot welding machines are used to weld iron, copper, aluminum, and other metals. AC resistance spot welding equipment needs no welding rods, nor does it damage the workpiece’s internal structure during the welding process. The high temperature generated through the contact resistance of the workpiece melts the metal between two electrodes, thus achieving workpiece welding.

Jiaxiao is a professional resistance spot welding manufacturer, and shown below are a few of our standard pieces of equipment. If you are interested in customized services, please contact us directly.

Model parameters- Power: 35KVA

Welding ability: plates with thickness of 2+2mm and wires with diameter of 5+5mm. - Power: 63KVA

Welding ability: plates with thickness of 3+3mm and wires with diameter of 8+8mm - Power: 100KVA

Welding ability: plates with thickness of 4+4mm and wires with diameter of 10+10mm -

- Power: 150KVA

Welding ability: plates with thickness of 6+6mm and wires with diameter of 12+12mm

-

- Power: 200KVA

Welding ability: plates with thickness of 7+7mm and wires with diameter of 13+13mm

-

- Power: 20KVA or 35KVA

Welding ability: wires with diameter of 2+2mm or 2.5+2.5mm

The upper and lower arms are an integral C type structure, with a high degree of rigidity, stable welding quality and low exhaust noise.

Equipped with pressure adjusting device and pressure gauge, it is easy to observe and operate.

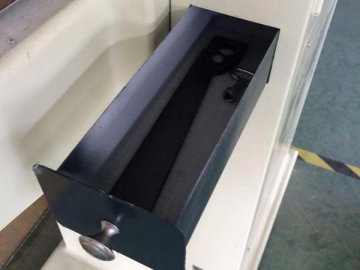

The tool box is designed in the remaining electric box space for easy tool storage.

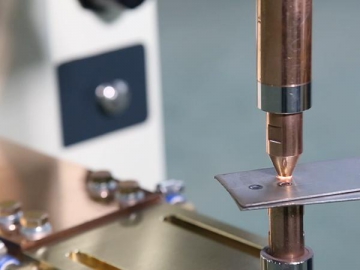

The electrode is made of high quality conductive material, which significantly reduces circuit impedance, and carries out highly efficient and energy saving welding processes.

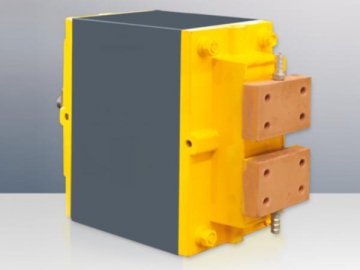

The resistance welding transformer is produced through an epoxy resin casting, and is shock resistant with a low electrical resistivity and a low loss.

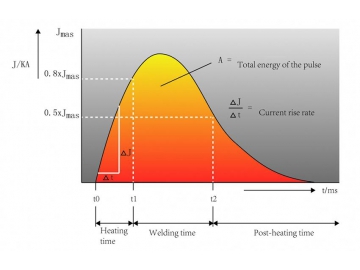

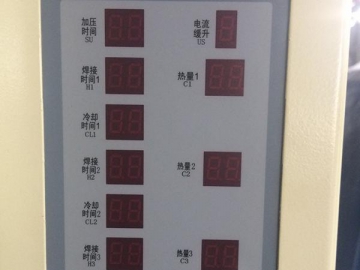

The current can be adjusted for different preheating, welding, tempering and different material thickness processes.