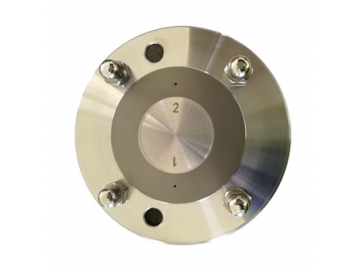

Polymer Fiber Spinning, Wet Spinning Spinneret

Introduction

We offer hollow fiber membrane spinnerets for non-solvent induce phase separation methods. The spinneret is made of a high quality stainless steel, with the highest connectivity reaching 0.003mm.

Suitable materials

PVDF (Polyvinylidene Fluoride), CA (cellulose acetate), PVC (Polyvinyl chloride), PES (Polyethersulfone), PSF/PSU (Polysulfone), PA (Nylon, Polyamide), PAN (polyacrylonitrile)

- Conventional design

- Independent design

We can provide a design that allows the spinneret to be removed, replacing conventional designs where each spinneret hole cannot be independently replaced and disassembled. If one has a quality problem, the entire spinneret needs to be either repaired or scrapped. Our spinnerets are designed independently, with each hole able to be individually replaced if needed.

What is a Nonsolvent Induce Phase Separation method?

Non-solvent induced phase separation, also known as NIPS, is the process by which a polymer is dissolved into a solvent in order to form a homogenous solution. A reagent is then added as an extracting agent that is more miscible with the solvent, thereby extracting the solvent in order to form a two phase structure with the polymer as a continuous phase and the solvent as a dispersed phase. The solvent is then removed in order to obtain a new polymer with a specific pore structure.

| No. | General Specification | Application | Design Type | Type |

| 1 | 0.36/0.28/0.15 | NIPS | Independent design | Single-aperture/ Multi-aperture |

| 2 | 0.5/0.28/0.15 | NIPS | Independent design | Single-aperture/ Multi-aperture |

| 3 | 0.6/0.4/0.2 | NIPS | Independent design | Single-aperture/ Multi-aperture |

| 4 | 0.8/0.4/0.2 | NIPS | Conventional design | Single-aperture/ Multi-aperture |

| 5 | 1.3/0.7/0.4 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 6 | 1.4/0.9/0.6 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 7 | 1.5/0.9/0.6 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 8 | 1.6/0.7/0.4 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 9 | 1.8/0.9/0.5 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 10 | 1.8/1.2/0.6 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 11 | 2.0/1.0/0.7 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 12 | 3.1/1.8/1.5 | NIPS | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

Trustech is a leading polymer fiber spinning spinneret manufacturer, by combined with advanced technology of fiber spinning process and equipment from Germany we can fabricate high quality spinneret, we can offer spinnerets used wet spinning, dry spinning, melt spinning for different fiber spinning process users, we have had clients who used our spinnerets to produce hollow fiber membrane for different filtration applications.

Index

hollow fiber membrane, wet spinning, melt spinning, drying spinning, spinning process