Mobile Hydraulic Valves

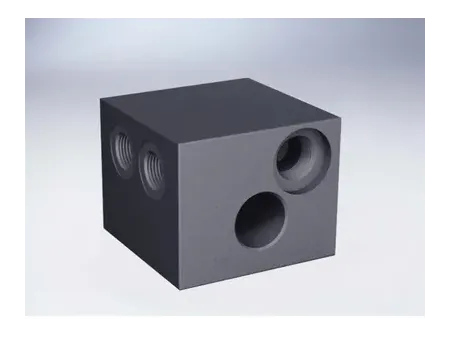

Dual hydraulic control check valves provide a compact and efficient solution for space-constrained hydraulic systems. By integrating two identical hydraulic check valves into a single valve body, they help streamline your system while ensuring precise fluid control. Unlike separate check valves, this design simplifies installation, removes the need for external control oil lines, and reduces overall system complexity, improving efficiency and maintenance.

These valves offer a practical way to enhance the efficiency of your mobile hydraulic system. Reach out to explore how they can improve your equipment’s performance!

- Flow (L/min): 20/30/55

- Max. Operating Pressure (bar): 350

- Flow (L/min): 30/55

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 25

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/35

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/30

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 30

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 35/50

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/35/45/50/70/100

- Max. Operating Pressure (MPa): 300/350

- Flow (L/min): 45

- Max. Operating Pressure (MPa): 350

For stable, precise hydraulic control, single hydraulic control check valves provide a straightforward, easy-to-maintain design. Built with a spring, valve, valve body, and control oil circuit, they are widely used in excavators, cranes, and other mobile machinery to support hydraulic cylinder locking, directional control, and system stability. Their simple construction minimizes maintenance downtime, ensuring consistent and reliable operation in high-demand environments.

Keep your equipment performing at its best. Let’s discuss how these valves can be integrated into your hydraulic system today!

- Flow (L/min): 20/35/45/50/70/100

- Max. Operating Pressure (bar): 350

- Flow (L/min): 20/30/55

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 15/30/45/80/120

- Max. Operating Pressure (MPa): 250/300/350

- Flow (L/min): 20/30/50

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/30/55

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/40/70

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/30/50

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 35

- Max. Operating Pressure (MPa): 350

Balancing valves are designed to maintain system stability and control movement in mobile hydraulic applications. Built with a combination of a poppet valve and a spool valve, they combine the functions of a check valve and a sequence valve, providing precise load control. In mobile machinery, these valves help ensure smooth operation in various working conditions, preventing sudden movements, improving safety, and enhancing operational efficiency. Contact us today for more details !

- Flow (L/min): 20/40/60/95

- Max. Operating Pressure (bar): 350

- Flow (L/min): 20/40/60/95

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 35/50/105

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60/95

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 35/50/105

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 40/60

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 50

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 35/50/105

- Max. Operating Pressure (MPa): 350

- Flow (L/min): 20/40/60/95

- Max. Operating Pressure (MPa): 350

Relief valves are essential for maintaining system pressure within safe limits, preventing excess pressure buildup that could damage your equipment. By adjusting the spool position or spring force, these valves regulate pressure with precision. Available in fixed, adjustable, and one-way/two-way configurations, relief valves adapt to various mobile hydraulic systems, giving you the flexibility to fine-tune your system’s pressure control.

Protect your system from pressure overload while maintaining optimal hydraulic performance with these reliable valves.

- Flow (L/min): 45/70

- Flow (L/min): 40/60

- Flow (L/min): 120/180

- Flow (L/min): 45/70/120

Two-way cross relief valves balance hydraulic pressure in both forward and reverse directions, preventing pressure spikes and ensuring smooth, consistent system operation. By adjusting the spool or spring settings, these valves provide accurate pressure control, reducing the risk of overload and improving equipment reliability. They are ideal for mobile hydraulic systems requiring dependable pressure management in multiple directions.

Optimize your hydraulic system with a pressure control solution that enhances stability, protects components, and keeps your equipment performing at its best.

- Flow (L/min): 30/45/70/110

- Flow (L/min): 45/70

- Flow (L/min): 45/70

- Flow (L/min): 35

- Flow (L/min): 70/110

- Flow (L/min): 160

- Flow (L/min): 50/60/100

- Flow (L/min): 60

2-position diverter valves efficiently split hydraulic flow from a single pump source into two or more separate paths, supplying multiple actuators such as hydraulic cylinders or motors. These valves allow for synchronized or independent hydraulic control, making them ideal for systems that require flexible fluid distribution.

Ensure your hydraulic system delivers power exactly where it’s needed with a flow control solution that enhances system efficiency and versatility.

- Flow (L/min): 3/6/10/20/32/40/60/80

- Max. Operating Pressure (bar): 300

- Flow (L/min): 30-60

- Max. Operating Pressure (bar): 300

- Flow (L/min): 10/20/40

- Max. Operating Pressure (bar): 300

Two pump unloading valves are designed to effectively control dual-pump systems, managing the operation of a high-pressure, low-flow pump and a low-pressure, high-flow pump. By unloading the secondary pump when not needed, these valves improve energy efficiency, reduce heat generation, and enhance overall system performance.

Achieve greater efficiency and smoother operation in your hydraulic system with a precise and reliable unloading valve solution.

- Flow (L/min): 40/65/100

- Max. Operating Pressure (bar): 350

- Flow (L/min): 40/65/100

- Max. Operating Pressure (bar): 350

High-pressure ball valves are built to withstand extreme pressure conditions while maintaining smooth and efficient fluid control. Designed for heavy-duty hydraulic applications, these valves provide secure shut-off and directional control, ensuring system integrity and leak-free operation. Their robust construction makes them suitable for high-pressure mobile and industrial hydraulic systems, where durability and precision are critical.

Ensure safe and reliable fluid control in high-pressure environments with a valve that delivers superior performance and longevity.

- The valve is used in the on-off circuit of high-pressure oil circuit.

- The valve diverts the inlet flow to 2 optional oil ports.

Diverter valves streamline hydraulic systems by integrating multiple functions within a single valve body, reducing piping complexity and potential leakage points. This enhanced system reliability makes them ideal for mobile machinery requiring efficient, multi-directional hydraulic flow control.

Enhance your hydraulic system’s efficiency and durability with a diverter valve solution designed for seamless fluid distribution.

- Flow (L/min): 35/60/100180

- Max. Operating Pressure (bar): 250

- Flow (L/min): 35/60/100

- Max. Operating Pressure (bar): 250

- Flow (L/min): 35/60/100/180

- Max. Operating Pressure (bar): 250

- Flow (L/min): 35/60

- Max. Operating Pressure (bar): 300

Stroke control valves integrate multiple functions within a single valve body, minimizing piping complexity and potential leakage points. This design enhances system reliability and precision, making them a great choice for applications that require accurate stroke control in mobile hydraulic systems.

Improve your system’s efficiency and ensure smooth, controlled hydraulic movement with a stroke control valve that enhances precision and reliability.

- Flow (L/min): 40

- Max. Operating Pressure (bar): 350

- Flow (L/min): 35/50

- Max. Operating Pressure (bar): 350

- Flow (L/min): 60/80/120

- Max. Operating Pressure (bar): 350

- Flow (L/min): 40/100

- Max. Operating Pressure (bar): 350

- Flow (L/min): 35/50

- Max. Operating Pressure (bar): 350

Tipping valves are constructed with high-strength, corrosion-resistant materials, ensuring reliable performance under high-pressure and high-flow conditions. These valves are designed to control the tilting mechanism of dump trucks, trailers, and other mobile applications, providing smooth and efficient load handling.

Enhance your equipment’s performance and stability with a tipping valve that delivers precise and reliable hydraulic control.

- Flow (L/min): 250

- Max. Operating Pressure (bar): 400

- Flow (L/min): 200

- Max. Operating Pressure (bar): 400

- Flow (L/min): Depending on actual needs

- Max. Operating Pressure (bar): 350

- Flow (L/min): 250

- Max. Operating Pressure (bar): 400

- Flow (L/min): 250

- Max. Operating Pressure (bar): 400

- Flow (L/min): 250

- Max. Operating Pressure (bar): 400

- Flow (L/min): 250

- Max. Operating Pressure (bar): 400

Looking for additional hydraulic valves? Contact us to explore our full range of hydraulic solutions tailored to your system’s needs.