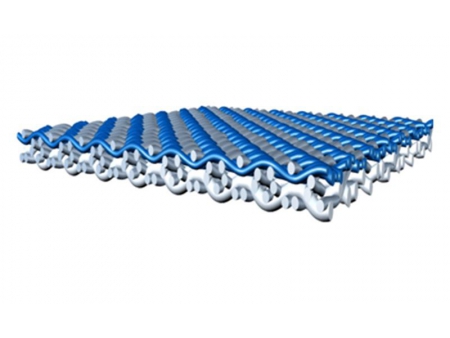

Refiners for Pulp Refining

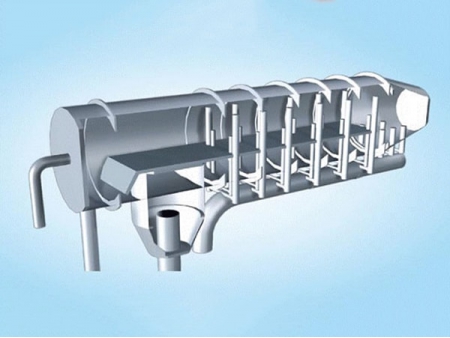

This double-disc refiner is able to modify pulp characteristics in consistency ranging from 2-5%. Equipped with an automatic control system, this pulp refining machine can work automatically, with power and effectiveness kept constant. Also, manual mode is available.

This double-disc refiner consists of two refining zones, a transmission system, a base and a motor. There are two refining zones inside, one between two discs fixed on the refiner body and the moveable base, and the other between two discs mounted on the refining plate. Blades can be changed to meet different pulping demands. During operation, stock will be pumped into the refining zone to create an abrasive effect. The refined stock will be obtained through the centrifugal force and feeding pressure.

Thanks to these features, the pulp refining machine is applicable for multiple kinds of pulp, including pulp with grass fibers, broke paper fibers, dicot tree fibers and conifer tree fibers, chemical wood pulp and chemical-mechanical pulp.

| Type | HT-380 | HT-450 | HT-500 | HT-550 | HT-600 | HT-660 | HT-720 | HT-900 | HT-1100 |

| Disc diameter (mm) | Ø380 | Ø450 | Ø500 | Ø550 | Ø600 | Ø660 | Ø720 | Ø900 | Ø1100 |

| Capacity (t/d) | 6-20 | 8-80 | 10-100 | 10-120 | 12-150 | 15-200 | 15-250 | 20-400 | 40-800 |

| Density (%) | 3-5 | ||||||||

| Motor power (kW) | 37 | 90-160 | 132-200 | 160-250 | 185-315 | 220-355 | 250-630 | 315-800 | 400-1250 |

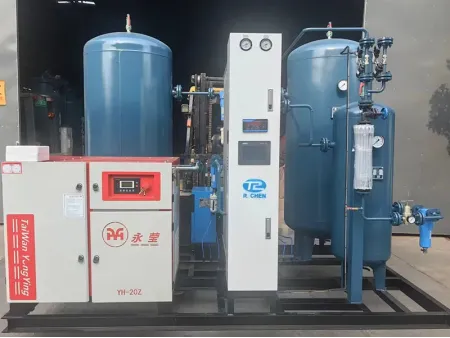

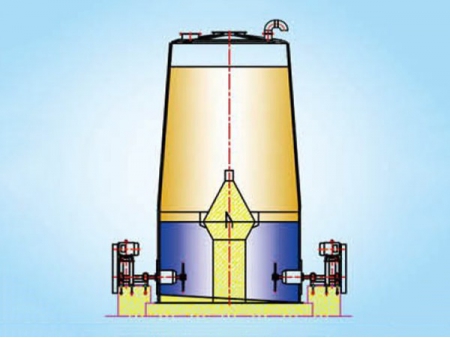

This conical refiner is equipped with conical rotor and stator that can refine bleached pulp effectively. The pulp refining machine is applicable for pulp with long fibers, such as cotton fibers, wood fibers and hemp fibers. The refined pulp features less fiber loss and good shape and uniformity. To be specific, the fracture length and bursting strength are largely improved. To enhance refining performance, this conical refiner can work independently or can be connected with a double-disc refiner or another conical refiner.