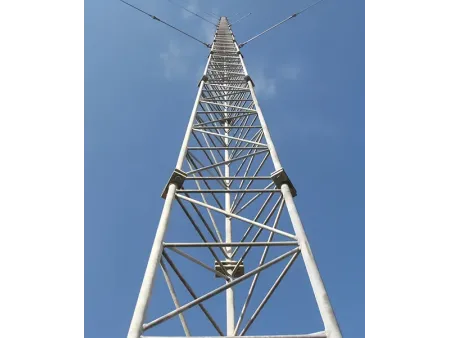

Guyed Communication Tower (Guyed Mast)

Guyed steel lattice towers braced by guy wires for telecommunication applications, available in height options from 5 to 200 meters

Guyed communication towers use a steel lattice structure reinforced by multiple sets of tensioned guy wires that are anchored directly to the ground. The tensioned guy wires help stabilize the tower and reduce the weight of the main structure, which means less steel is required compared to self-supporting towers. Thanks to this design, guyed towers provide an efficient and cost-effective option for large-area communication coverage. They also perform well under strong wind conditions, although the anchor system requires more installation space around the tower.

- Standard ANSI/TIA-222-G/H/F; EN 1991-1-4; EN 1993-3-1

- Height 5–200 m

- Wind Speed 0–300 km/h (as per customer requirements)

- Surface Treatment Hot-dip galvanized; Painting

- Main Components

Guyed communication towers have a structure made up of the tower head, main shaft, and guy wires. The tower head and main shaft are usually built with angle steel or steel pipes assembled into a spatial truss structure. The guy wires are typically made of high-strength steel strands. - Structural Stability

The guy wires take on part of the forces acting on the telecom tower, which helps it stay stable while supporting both vertical and tension loads. This design also improves material efficiency by making better use of the steel.

Typical Installation Environments

Guyed towers are usually installed in rural or mountainous areas where visual impact is less of a concern and land costs are lower. A flat area with firm ground is usually chosen because it makes the installation process simpler and helps avoid future stability issues.

| Product | Telecommunication tower |

| Tower Type | Guyed Wire Tower |

| Standard | ANSI/TIA-222-G/H/F; EN 1991-1-4; EN 1993-3-1 |

| Certification | ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV) |

| Nuts & Bolts | Grades 8.8 / 6.8 / 4.8; A325; DIN 7990; DIN 931; DIN 933; ISO 4032; ISO 4034 |

| Material | Tube steel, round steel, angle steel |

| Height | 5–200 m |

| Wind Speed | 0–300 km/h (as per customer requirements) |

| Surface Treatment | Hot-dip galvanized; Painting |

| Galvanizing Standard | ASTM A123 / ISO 1461 |

| Lifetime | More than 20 years |

| Color | Silver or painted finish (RAL color standard), customizable |

| Certification Standard | ||

| Design Standards |

| |

| Structural Steel | ||

| Grade | Mild Steel | High Tensile Steel |

| GB/T 700 – Q235B, Q235C, Q235D | GB/T 1591 – Q355B, Q355C, Q355D, Q420B | |

| ASTM A36 | ASTM A572 Gr.50 | |

| EN 10025 – S235JR, S235J0, S235J2 | EN 10025 – S355JR, S355J0, S355J2 | |

| Design Wind Speed | Up to 300 km/h | |

| Allowable deflection | 0.5–1.0° @ operational speed | |

| Tensile strength (MPa) | 360–510 | 470–630 |

| Yield strength (t ≤ 16 mm) (MPa) | 235 | 355 / 420 |

| Elongation (%) | 20 | 24 |

| Impact strength KV (J) | 27 (20°C) - Q235B (S235JR) | 27 (20°C) - Q355B (S355JR) |

| 27 (0°C) - Q235C (S235J0) | 27 (0°C) - Q355C (S355J0) | |

| 27 (-20°C) - Q235D (S235J2) | 27 (-20°C) - Q355D (S355J2) | |

| Bolts & Nuts | ||

| Grade | Grade 4.8, 6.8, 8.8 | |

| Standards for mechanical properties | ||

| Bolts | ISO 898-1 | |

| Nuts | ISO 898-2 | |

| Washers | ISO 7089 / DIN 125 / DIN 9021 | |

| Standards for dimensions | ||

| Bolts (dimensions) | DIN 7990, DIN 931, DIN 933 | |

| Nuts (dimensions) | ISO 4032, ISO 4034 | |

| Washers (dimensions) | DIN 7989, DIN 127B, ISO 7091 | |

| Welding | ||

| Method | CO₂ Shielded Arc Welding & Submerged Arc Welding (SAW) | |

| Standard | AWS D1.1 | |

| Galvanizing | ||

| Galvanization standard of steel sections | ISO 1461 or ASTM A123/A123M | |

| Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153/A153M | |

Main Components

- Anchor Bolts

- Antenna Mounting Bracket

- Copper Grounding Components

- Connection Plates

- Antenna Mast

Optional Components

- Communication Tower Bolts

- Aviation Obstruction Light

- Climbing Ladder

- Copper Lightning Rod

- Grating Platform and Mesh Platform

- Guy Wire

- Shackle

- Turnbuckle

- Wire Rope Wedge Clamp

- U-Bolt Wire Rope Clamp

We provide full technical guidance and carry out construction based on the approved drawings. If any questions arise, we are always available to assist.

Part of the load in guyed towers is carried by the guy wires, so the main structure does not need to be as heavy as a self-supporting tower. Since the structure uses lighter steel sections, less material is needed, which helps keep construction costs at a more reasonable level.

The structure of a guyed tower is simple, which makes the installation process easier to handle on site. With fewer complicated assembly steps, construction can be completed in a shorter time, helping reduce installation time and labor costs.

Correctly installed guy wires help keep the tower steady when it is exposed to wind and other external forces. On soft or unstable ground, the anchoring systems help spread the weight over a wider area instead of placing all the stress in one point. Uneven ground movement is reduced, helping the structure remain safe and stable over long-term operation.

- 60m Guyed Communication Tower

- 50m Guyed Communication Tower

- 60m Guyed Communication Tower

Laser Cutting

Laser cutting is used to shape the steel components through focused beam cutting and assisted gas removal. The process offers fast cutting speed and high dimensional accuracy (up to ±0.05 mm), while keeping heat impact to a minimum. This reduces the risk of deformation and results in clean, well-defined edges.

CNC Punching and Shearing

Steel angles are processed through CNC-controlled punching and shearing lines. Automatic feeding, positioning, punching, and cutting are all integrated into the process, keeping production running smoothly and efficiently. Precise CNC positioning keeps quality consistent, even when working with more complex parts.

Hot-Dip Galvanizing and Surface Protection

The tower is protected with hot-dip galvanizing as the main anti-corrosion treatment, along with an extra plastic coating for added protection. The zinc layer protects the steel from rust and adds strength, while the coating gives extra insulation and surface protection. This combined treatment allows the tower to maintain reliable performance for over 20 years and adapt well to harsh environments such as high and low temperatures, coastal areas, and mountainous regions.