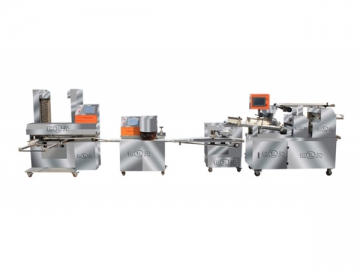

Pie Production Line

Our pie production line is used to produce pastries and pies and is applicable to large and medium-scale pie producers. It is comprised of a three roller dough sheeter, dough shaping and forming machine, stuffing filling machine, handwork-imitating cake rolling machine, automatic tray arranging machine and other fitting equipment.

Processing line detail displayPut the kneaded dough on the conveyor belt.

Enters dough sheeter, and the dough sheet thickness is adjustable by adjusting the handle.

Feeding stuffing through stuffing filling machine.

It is rolled into circular column by dough roller.

With forming machine, the pie is shaped and formed.

Tray arranging.

The dough skin is rolled and extended through a three roll dough sheeter and dough rolling device. Thus the dough shin is glossier and more stable in quality. Each dough roller has thickness adjusting device used for setting dough wrapper thickness. This aims to increase or reduce the product weight.

Filling by multiple feeding methods, the stuffing is consistent and stable.

It is used in the surface treatment of the pastries and pies. And their surface shapes can be set according to the operator's requirements.

This machine is used in the handwork-imitating of various cakes. The rolled products have uniform thickness with adjustable thickness and size.

The products need no manual tray arrangement. The produced pies and pastries are arranged into the trays in parallel or cross arrangement. Different machine models are customized based on the various tray sizes.

| Overall size (L x W x H) | 9800x1400x1500mm |

| Output | 1000-6000 6000pcs/h |

| Equipment power | 9.5kw |

| Equipment weight | 1950kg |

| Equipment voltage | 220/380V |

| Finished product weight | 10-150g/pc (special size can be customized) |

| Equipment frequency | 50HZ/60HZ |

| Ratio of wrapper and stuffing | adjustable |

- The whole machine unit is equipped with a complete set of Japanese cutters, German SIKE photo electricity system, Taiwanese drive motor, Taiwan inverter, Italian SAMPLA conveying belt, etc.

- All the parts contacting with the food are made of high quality stainless steel to ensure stable, reliable and hygienic production.

- The whole set equipment consumes about 9.5kw/h. with low energy consumption and easy operation, it can be operated only by 3-4 person.

- This machine has high production speed, as much as 6000 pies per hour.