Ready Mix Concrete Batching Plant

HZS Series

- Production Capacity 90–270 m³/h

- Plant Configuration Eco-friendly ready-mix plant with flexible batching options

As urban construction transitions toward commercial ready-mix and sustainable production, the company has updated its batching plants to prioritize environmental compliance and efficiency. These plants offer stable performance and are widely utilized by ready-mix producers.

The series supports both steel-bin and ground-type aggregate batching configurations. Steel-bin units use sectional assembled panels for rapid installation, while ground-type units utilize reinforced concrete retaining walls to achieve higher storage capacities. Belt conveyors can be equipped with cleaners, collection chutes, and washing systems for material recycling. To minimize environmental impact, the main tower includes a pulse dust collection system, with optional color steel enclosures available for further dust and noise reduction.

Technical Parameters

| Model | | | | | |

| Theoretical capacity (m³/h) | 90 | 120 | 180 | 240 | 270 |

| Mixer model | JS1500B | JS2000B | JS3000B | JS4000B | JS4500B |

| Aggregate batching machine model | HP2400A/D | HP3200B/D | HP4800C/D | HP6400B/D | HP7200B/D |

| Single bin capacity of batching machine (m³) | 12/14 | 17 | 22 | 30 | 32 |

| Belt conveyor capacity (t/h) | 400 | 500 | 700 | 800 | 800 |

| Screw conveyor model | LSY219/ LSY273 | LSY219/ LSY273 | LSY219/ LSY273/ LSY325 | LSY219/ LSY273/ LSY407 | LSY219/ LSY273/ LSY407 |

| Cement bin capacity | 100T/150T/200T/300T optional | ||||

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Fly ash weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Mineral powder weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Admixture weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Approx. total power (kW) | 135 | 170 | 220 | 280 | 280 |

| Discharge height (m) | 4.1 | 4.1 | 4.2 | 4.2 | 4.2 |

Notes:

- The quantity and capacity of aggregate bins and cement bins are fully customizable. Weighing systems can be configured for either cumulative or individual measurement based on project requirements.

- Total power consumption ratings exclude the power requirements of screw conveyors.

- Standard discharge height is measured from the outlet of the discharge hopper.

- Specifications are subject to optimization and may change without prior notice. Please consult the latest product documentation for finalized data.

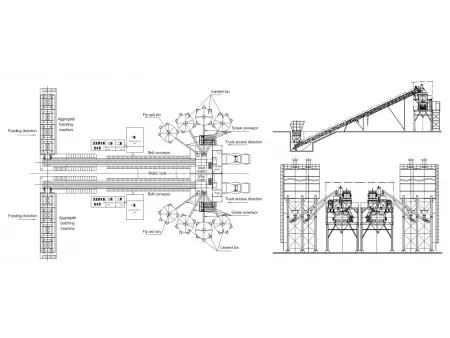

Process Flow

Main Components

Concrete Mixer

Equipped with JS series standard twin-shaft concrete mixer, featuring fast mixing speed, high homogeneity, and stable, reliable performance.

Aggregate Batching Machine

Available in steel aggregate bin or concrete wall aggregate bin. The steel aggregate bin features a modular panel assembly for easy installation, while the concrete wall aggregate bin utilizes reinforced concrete walls for larger storage capacity.

Belt Conveyor

The belt conveyor systems are fully customizable, offering chevron, trough, or flat belt configurations to suit specific site layouts. To ensure operational safety and minimal downtime, the conveyor system features a belt deviation alarm for real-time tracking adjustments. Each unit is equipped with dedicated maintenance walkways and comes standard with protective rain covers, material collection chutes, and integrated washing systems. These features not only facilitate the recycling of residual materials but also ensure full environmental compliance and a clean, professional appearance.

Screw Conveyor

Powder screw conveyors use high-quality steel pipe casings, with sections connected by flanges. Variable-pitch screw blade design ensures smooth powder conveying. Universal joints are included for convenient on-site installation.

Weighing System

The weighing system is equipped with high-precision load cells to ensure consistent and accurate measurement.

For material release, it utilizes pneumatically operated butterfly valves of premium quality, providing rapid actuation and a hermetic seal to prevent leakage.

Main Tower

Steel structure or reinforced concrete frame main towers can be selected according to site conditions. Steel structure tower adopts a modular and sectional structural design, making transportation and installation more convenient. Optional color steel enclosure is available to reduce noise and dust pollution, providing an environmentally friendly solution.

Project Cases

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.