Vacuum Kiln For Veneer and Floor Drying

The vacuum kiln is specially designed for wood veneer and flooring drying. It comes with great difference in drying process with RFV kilns for drying of thick wood and hardwood. The face veneer of wood veneer and flooring is so thin that drying needs large power. Hence, this radio frequency vacuum kiln is outfitted with a unique stainless steel cooling system which can effectively remit the load of vacuum system, thus improving drying efficiency.

Technical Parameters of the Vacuum Kiln

| Capacity | 3CBM | 4CBM | 6CBM | 10CBM | 13.5CBM | 20CBM |

| Model | ||||||

| Power | AC 380V 50HZ 3phase 5wire or customized | |||||

| Output Power | 20KW--100KW | |||||

| 21 years experience in high frequency (HF) technology. Machine can save power and improve efficiency. | ||||||

| Wood loading size | L3000mm × W 1000 × H 1000 (3 CBM capacity) | |||||

| L4000mm × W 1000 × H 1000 (4 CBM capacity) | ||||||

| L6000mm × W 1000 × H 1000 (6 CBM capacity) | ||||||

| L6000mm × W 1300 × H 1300 (10 CBM capacity) | ||||||

| L8000mm × W 1300 × H 1300 (13.5 CBM capacity) | ||||||

| L8000mm × W 1600 × H 1600 (20 CBM capacity) | ||||||

| Other capacities can also be customized. | ||||||

| Functions | The vacuum wood dryer can dry all kinds of wood, especially for thin board, slicing veneer, peeling veneer. | |||||

| Faster, uniformly, no bending and crack problems. | ||||||

| High frequency | 6.78MHz | |||||

| Max pressure | -0.092MPa | |||||

Under the function of radio frequency uniform heating and vacuum low temperature drying by this vacuum kiln, the wood veneer and floor comes with rapid temperature rising and high evaporation rate, thus not easy to crack. In addition, during drying process, the flatness of wood veneer is of great importance. So, we equip hydraulic system for our veneer dryer. When drying, the hydraulic system will exert pressure on wood veneer and flooring. As a result, the flatness and quality can be effectively ensured after drying, thus saving considerable cost for customers and improving benefits.

JIYUAN, as a leading woodworking machine manufacturer, has accumulated 21 years of experience in radio frequency technology and developed PLC automatic control input program. Before drying, the vacuum kiln will automatically recommend drying procedure. The operators only need to input volume, density and target moisture content of the wood to be dried. Then, the system will automatically operate and adjust. When the moisture content reaches the input number, the wood drying kiln will automatically stop running and notice operators.

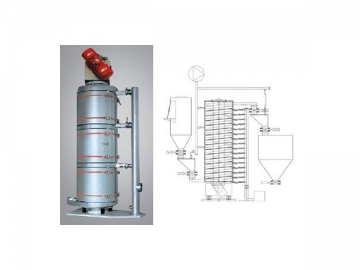

Parts Figure

- Shielding net

- Stainless steel cooling and condensing system

- Hydraulic system and stainless steel press

Appliaction

- Wood Flooring Drying

- Slicing Veneer Drying

- Peeling Veneer Drying