Steam Jet Mill

Request a Quote

HS

The HS Steam Jet Mill uses superheated steam as the medium and supersonic nozzles to accelerate the steam into a super high speed air stream, then the material is crushed under high speed motion and collision.

Features

- Compared to conventional jet mills, the impact force on particles of this equipment is increased by 4 times, but the energy consumption is only 1/5-1/8 of conventional equipment.

- The classifier works in a high-temperature steam environment, the particle size cutting point of the classifying wheel is smaller than that in the air environment, and can produce directly the products of D50<1um.

- The steam flow in the ultra-high temperature state is dry, which not only will not increase the moisture content of the material, but also has a material drying function.

- Especially suitable for ultra-fine pulverization of high-viscosity materials. The finished products have poor electrostatic agglomeration and good dispersibility.

- It can make full use of the unused or discharged low-grade superheated steam in electric heating plants and steel mills to achieve low-cost and large-scale ultra-fine powder processing.

- High capacity, it can be used with large industrial boilers

Application

Applicable materials: steel slag, water slag, fly ash, solid sulfur residue, kaolin, titanium dioxide, carbon black and other low-cost processing materials.

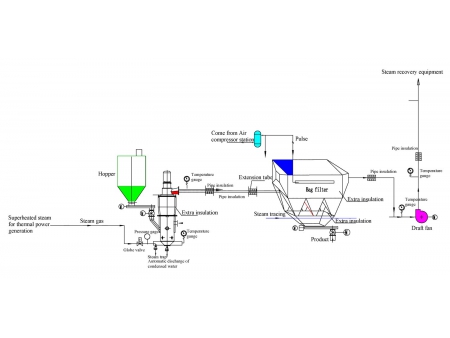

Process Flow