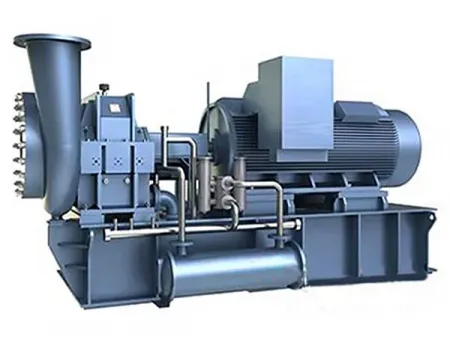

Steam Screw Compressor

The steam screw compressor is a highly efficient machine designed to recover and utilize low-grade thermal energy. It operates by mechanically driving a screw mechanism, where low-grade heat mediums are compressed within the rotor grooves as they spin. This action rapidly decreases the volume of the grooves, facilitating fluid compression and energy transformation. This process effectively upgrades waste heat steam from a low to a high-quality state, outputting high-temperature, high-pressure steam that meets the specific steam parameters required by users. Moreover, the steam screw compressor supports the recycling of steam in industrial production, resulting as an eco-friendly option by achieving energy savings and emission reduction goals, thus offering significant economic benefits to enterprises.

- Pressure differential

0.2-1.0Mpa

- Temperature range

20-100℃

- Max. discharge temperature

250℃

- Speed

1500-4000r/min

- Free air delivery

20-320m³/min

- Steam compression

0.5-20t/h

The steam screw compressor is widely used across various industrial sectors such as petroleum, chemical, metallurgy, thermal power, steel, paper, and light industries for the recovery and utilization of low-pressure steam.

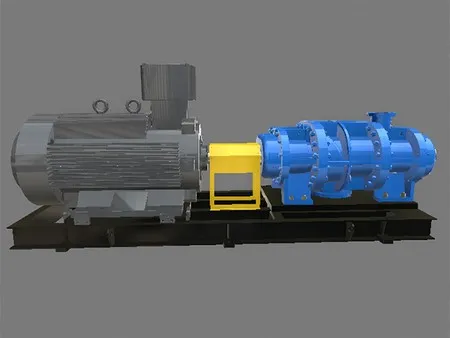

Features- Simple, Safe, and Reliable Structure

The steam screw compressor has a simple structure, compact size, stable operation with minimal vibration, and is durable, safe, and reliable. It is easy to operate and maintain, delivered fully assembled from the factory and ready to operate after on-site connection and testing.

- Wide Pressure Differential, Strong Applicability

The compressor can handle a maximum steam pressure differential of up to 1MPa, significantly surpassing other steam boosting equipment. It achieves a high-quality heat source with minimal energy consumption and is suitable for boosting pressure in saturated steam, vapor-liquid two-phase, and other mediums.

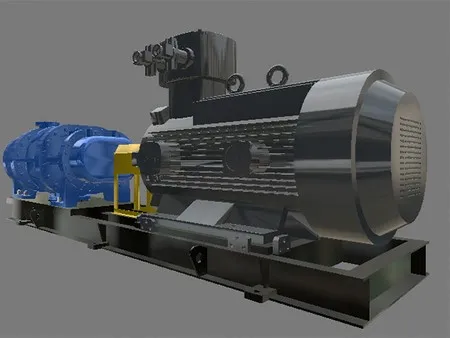

- Forced Steam Delivery, Adjustable Parameters

Characterized by its forced steam delivery, the volumetric flow rate of this compressor is almost unaffected by the discharge pressure. It maintains high efficiency across a broad range and can adapt to various operational parameters without any structural modifications.

- Significant Energy Savings, Quick ROI

By boosting low-pressure steam for recycling applications, it substantially reduces or even eliminates the extensive energy consumption associated with steam condensation, boosting, and reheating. This results in significant energy savings by recovering process steam and tail steam.

For detailed specifications and further information, please refer to our