Screw Refrigeration Compressor Unit

Screw compressor package for refrigeration and freezing

Screw refrigeration compressor units are widely used in industries that require artificial low-temperature environments. They are commonly used in food freezing and storage, gas liquefaction, process cooling, and applications like construction aggregate cooling, mining heat management, and permafrost excavation. These screw refrigeration compressor units offer customizable configurations, including energy regulation options such as variable volume ratio control and frequency conversion. With automatic control as a standard feature, the compressor units also support cloud-based monitoring for real-time data sharing and operational efficiency. Compact and versatile, screw refrigeration compressor units deliver reliable performance tailored to industrial demands.

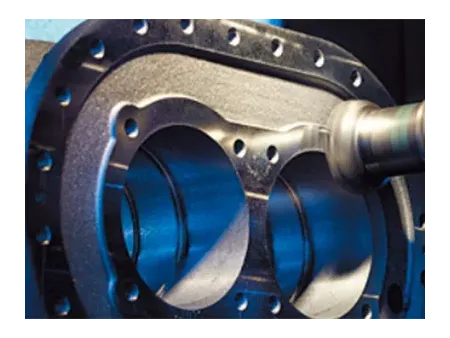

Screw Compressor Housing

The compressor housing manufactured using advanced machining centers from Japan and Germany, ensuring exceptional accuracy and durability in every unit.

Shaft Seal

Crafted from silicon carbide, the shaft seal features a simple structure, easy installation, and excellent sealing performance. It is suitable for applications with varying operating conditions.

Bearing

Thrust bearings, made with high-precision materials designed for low-temperature applications, are sourced internationally to ensure top performance. These bearings are resistant to corrosion, aging, and high temperatures, providing reliable and long-lasting precision in rotor positioning without compromising operational stability.

Sealing Elements

We provide sealing elements from internationally recognized brands, ensuring durability and reliability. Seal materials are carefully selected based on the specific refrigerant used, guaranteeing optimal performance and enhanced sealing across all components.

Motor

A high-efficiency, custom-designed three-phase asynchronous motor is engineered to meet national standards, ensuring energy savings and reduced power consumption. With a well-optimized structure, it delivers excellent performance, low noise levels, and can be customized for specific voltage and frequency requirements based on user needs.

Coupling

Screw refrigeration compressor units use diaphragm couplings designed to reduce vibration and isolate shocks. These couplings feature self-aligning capabilities and are engineered for long service life, ensuring reliable and efficient operation.

Oil Filter

The oil filter incorporates a high-precision, washable stainless steel filter element, providing exceptional filtration performance. This ensures clean lubrication oil, enhancing the reliability and longevity of both the oil pump and the compressor.

Oil Pump

Oil pumps deliver consistent oil flow and pressure, thanks to its priming capability. Equipped with a high-temperature-resistant and corrosion-proof mechanical shaft seal, it offers extended durability and reliable performance tailored for demanding refrigeration applications.

Automatic Control System

The automatic control system is equipped with multiple safety features, including load limit warnings, over-limit alarms, and automatic shutdown in case of critical conditions. These protections ensure the safe and stable operation of the compressor.

- Electrical Heater

Maintains the lubrication oil at a stable temperature inside the oil separator, ensuring reliable startup of the unit in low ambient conditions. - Double Oil Filter

Optional double oil filter setup allows switching between filters without shutting down, providing continuous operation. - Water-Cooled Oil Cooler

Depending on site conditions, a water-cooled oil cooler can be selected. Various materials for shells and heat exchange tubes are available to match specific water quality requirements. - Instrument

Options include internationally recognized brands like Rosemount and EJA for pressure and temperature sensors and transmitters, tailored to specific needs. - Oil Temperature Control

High-precision oil temperature control valves from renowned global brands can be configured to maintain the optimal lubricant temperature, ensuring reliable unit operation. - Explosion-Proof Unit

Customizable explosion-proof equipment can be provided based on the operational environment. Instruments, valves, and electrical components meet explosion-proof standards and comply with ATEX, IEC, or other systems as required.