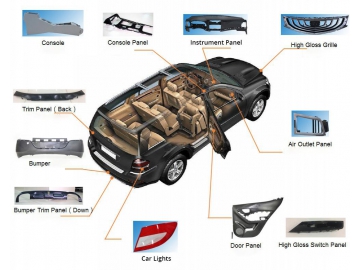

Automotive Precision Mold

- Console

- Console panel

- Instrument panel

- High gloss grille

- Trim panel (back)

- Bumper

- Air outlet panel

- Bumper trim panel (down)

- Car lights

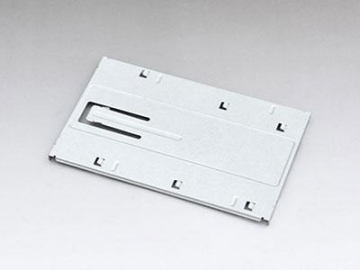

- Door panel

- High gloss switch panel

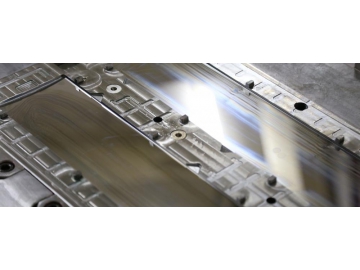

- High gloss steam free spraying

- Silver free spraying

- In mold transfer printing process

- Micro foaming technology

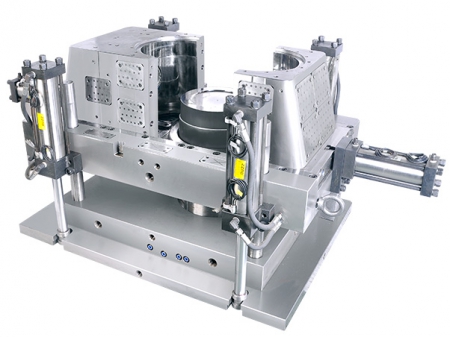

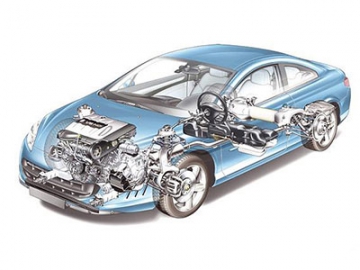

ECHOM has a unique design concept and manufacturing technology so that we can offer customers high-quality molds for automotive bumpers, instrument panels, doors and other large complex molds.

We have a strong R & D and design team and we have achieved magnificent results in the addition of fiberglass and high deformation requirements for front-end frames, grille mounting gratings and plastic tailgates of automobiles. We have also significantly shortened product development cycles, earning us a better reputation.

ECHOM is adept at applying superior technologies to other fields. We expand high gloss steam free spraying technology, a concept popular in the field of household appliances, to automotive intake grille, console panel, and door switch panels. We have also reduced customer products while significantly improving production efficiency.

Samples of automotive molds we producedECHOM Science & Technology Group is the parent company of ECHOM mold. We focus on the design and production of plastic molds used to create components for the manufacturing of cars and electronics. We fabricate molds used in the production process of brands such as Ford, BMW, Mercedes, Toyota, Honda, and electronics appliances part molds like Sharp, Panasonic, Sony, Midea, and TCL. We employ a number of advanced processing technologies and methods to create high quality molds for our customers.

Index

auto part mold maker, car part mold, plastic mold manufacturer