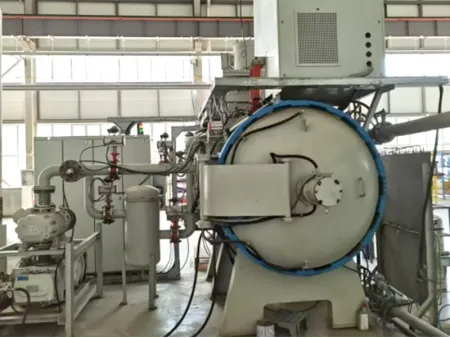

Vacuum Quenching Furnace

Vacuum Heat Treatment Furnace

Our vacuum quenching furnace performs quenching processes under vacuum or inert gas protection, ensuring automated and efficient heat treatment. The system cools heated metal materials using high-purity inert gases injected after vacuum extraction, as well as vacuum quenching oils and water-based solvents.

This furnace is ideal for various processes, including the shaping and surface finishing of high-speed steels, precipitation hardening, vacuum annealing, and high-temperature welding and solution treatment of stainless steels. It also supports the sintering and timely processing of powder materials, offering rapid cooling for annealing and solution treatment processes.

Vertical Double Chamber Vacuum Quenching Furnace

| Model | |||||

| Effective internal dimensions (mm) | 400×400 | 400×600 | 500×400 | 500×600 | 600×600 |

| Max. load capacity (kg) | 30 | 60 | 60 | 90 | 120 |

| Heating power (kW) | 30/45 | 40/60 | 50/75 | 60/90 | 70/100 |

| Max. temperature (℃) | 1050/1320 | 1050/1320 | 1050/1320 | 1050/1320 | 1050/1320 |

| Ultimate vacuum level (Pa) | 4×10⁻³/4×10⁻⁴ | 4×10⁻³/4×10⁻⁴ | 4×10⁻³/4×10⁻⁴ | 4×10⁻³/4×10⁻⁴ | 4×10⁻³/4×10⁻⁴ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. cooling gas pressure (bar) | 1 | 1 | 1 | 1 | 1 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

| Transfer time (S) | 5 | 6 | 5 | 6 | 6 |

The above parameters are for the standard vertical double-chamber water quenching vacuum furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

Vertical Double Chamber Vacuum Quenching Furnace

| Model | |||||

| Effective internal dimensions (mm) | 800×1200 | 800×1600 | 900×2000 | 1200×1600 | 1200×2000 |

| Max. load capacity (kg) | 600 | 800 | 1000 | 1200 | 1500 |

| Heating power (kW) | 180 | 260 | 390 | 360 | 440 |

| Max. temperature (℃) | 1320 | 1320 | 1320 | 1320 | 1320 |

| Ultimate vacuum level (Pa) | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. cooling gas pressure (bar) | 1 | 1 | 1 | 1 | 1 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

| Transfer time (S) | 18 | 22 | 25 | 22 | 25 |

The above parameters are for the standard vertical double-chamber oil quenching vacuum furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

Vertical Double Chamber Vacuum Quenching Furnace

| Model | |||||

| Effective internal dimensions (mm) | 600×400×400 | 700×500×500 | 900×600×600 | 1200×600×600 | 1200×900×900 |

| Max. load capacity (kg) | 200 | 300 | 500 | 800 | 1200 |

| Heating power (kW) | 50/65 | 65/85 | 90/120 | 120/160 | 180/240 |

| Max. temperature (℃) | 1100/1320 | 1100/1320 | 1100/1320 | 1100/1320 | 1100/1320 |

| Ultimate vacuum level (Pa) | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ | 4×10⁻¹/4×10⁻³ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. gas quenching pressure (bar) | 6 | 6 | 6 | 6 | 6 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

Note: The above parameters are for the standard vertical double-chamber gas quenching vacuum furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

- Provides safe and eco-friendly heat treatment solutions, using clean energy, reducing harmful emissions, and ensuring operational safety.

- Designed for operational flexibility, allowing the furnace to be started and stopped as needed to reduce energy waste and optimize production cycles.

- Ensures high surface quality and minimal deformation during heat treatment, enhancing product reliability.

- Features advanced automation capabilities, reducing manual intervention and significantly improving production efficiency.

- Designed for ease of maintenance and cost efficiency, reducing downtime and operational expenses.