Concrete Batch Plant Spare Parts

HT-HI provides all kinds of high-quality wearing parts for the casting industry. Our castings are produced from abrasion resistant iron with a minimum hardness of 550 brinell hardness. The accessories of HT-HI can work with concrete for as long as 70-80 thousand times.

- We offer the following castings

- Wear Liner

- Mixing Blade

- Mixing Arm

- Casting Wear Ring

- Cast Iron Spacer

- Wear Plate

Concrete Mixer Brands Supported:

Germany: BHS, LIEBHERR, LINTEC, TEKA

Japan: NIKKO, KYC, IHI, KURIMOTO

Italy: SICOMA

Korea: SPECO

China: SANY, ZOOMLION, XCMG, YUESHOU, NFLG

Material Standards

Casting steel: DIN, JIS, EN, ASTM, GB

Manganese steels: with a Mn content of 13%-17%

White chromium alloy castings, Cr content of 8-29%

Ni hard cast iron: containing 2-6%

Low alloy martensitic steels

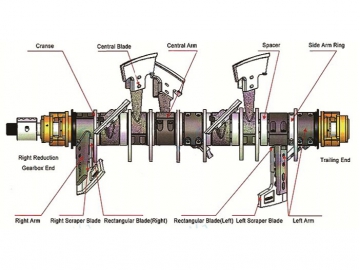

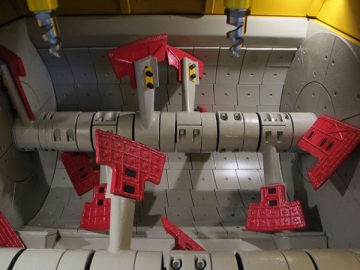

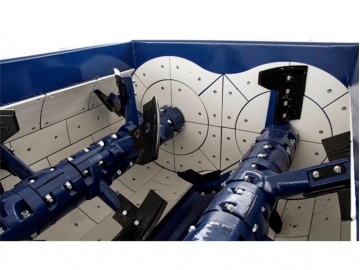

- Mixing arm for concrete mixer

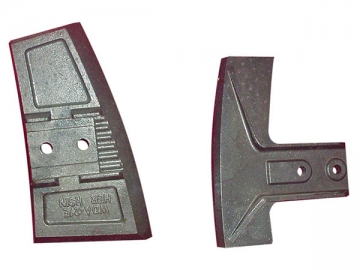

- Mixing blade

- Spacer & ring

- Wall liners

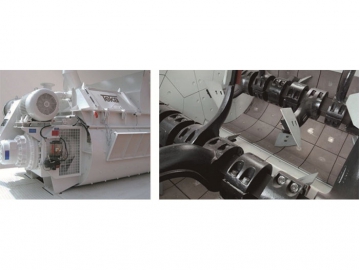

- On-site installation

Why Choose Us

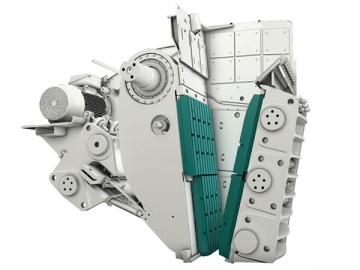

We strictly control all performance parameters of our products. Currently HT-HI is China’s largest manufacturer of abrasion-resistant parts for both concrete and asphalt mixers. Our manufacturing facilities occupy an area of 58,000 square meters. We have 6 advanced production workshops and one R&D center. Each year we have the capacity to produce 20,000 tons of wear-resistant Cr/Mn hard cast iron castings.

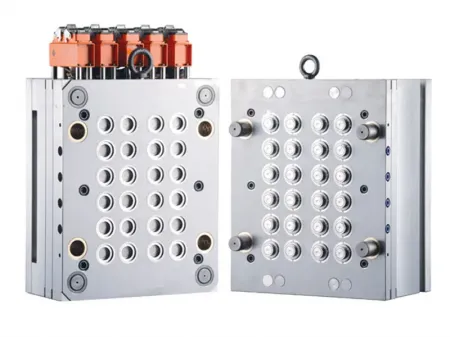

- Precise mold making: We utilize the most advanced 3D simulation PROCAST & Solidworks 3D software, in order to guarantee a high-precision mold making and casting process.

- Fully automatic production line: The Denmark DISA MATIC 200 vertical molding line operates with a high level of automation. The sand which has been sorted can be recycled. The entire manufacturing process is energy-efficient and friendly to environment.

- Constant-temperature casting: Constant-temperature casting and casting purity can be guaranteed with the use of Japanese Toshiba constant-temperature casting control system and patented filter screen.

- Strict quality control: Direct-reading spectrometers from Thermo Fisher and Barid are adopted. The production process is monitored in real time for the purpose of quality control.

- Health and safety is at the center of everything we do, from the daily routines in our plants to our customers' project worksites.

- How to Place an Order

- Tell us the brand and specification of your equipment.

- Give us the drawings or samples, and we will design and manufacture according to what clients have provided.

- The finished parts are sent to customers to confirm.

You can order our concrete batching plant spares and mixing plant accessories in 3 ways: