Asphalt Paver Replacement Parts

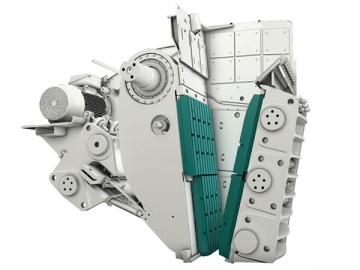

HT-HI castings are produced with an abrasion resistant iron with a minimum of 550 brinell hardness. The lifespan of our asphalt paver replacement parts is more than twice as long as that of ordinary wear-resistant parts. Most of the world’s leading OEMs and 1st tier suppliers in concrete construction, paving machine, crusher, vertical mill and other demanding markets continue to rely on HT-HI because we provide the capability to meet exacting demands, the capacity to handle high volumes, the value-adds to shorten the supply chain and the expertise and agility to evolve with changing needs.

- We offer the following castings

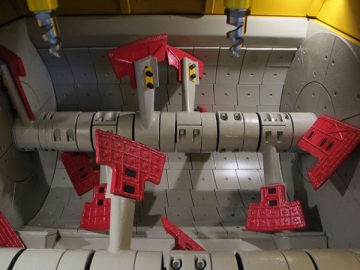

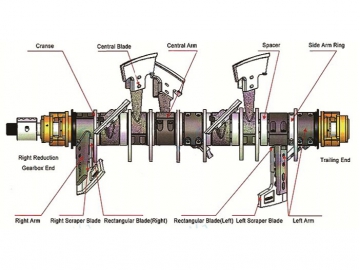

- Auger Blade

- Bottom Wear Plate

- Casting Wear Ring

Paver Brands Supported

China: XCMG, SANY, ZOOMLION

Other: VOGELE, VOLVO, DYNAPAC, DEMAG, WIRTGEN, BENNINGHOVEN

Material Standards

Casting steel: DIN, JIS, EN, ASTM, GB

White chromium alloy castings: Cr content of 8%-29%

Ni hard cast iron: containing 2-6%

Manganese steels: with a Mn content of 13%-19%

Low alloy martensitic steels

- Paver auger blade

Paver auger blade

Paver auger blade

Why choose us

HT-HI is currently the Chinese largest manufacturer of wear-resistant parts for both concrete and asphalt mixing machines. Each year we can produce 20,000 tons of abrasion-resistant Cr/Mn hard cast iron castings. Our manufacturing complex spans a total area of 58,000 square meters. We use 6 large production workshops and fully automatic machines to guarantee both the production efficiency and product quality.

- Precise mold making: We use the most advanced 3D simulation PROCAST & Solidworks 3D software to ensure a high-precision mold making and casting process.

- Advanced technology: HT-HI avails itself of DISA vertical automated moulding installations for green sand moulding and chemical moulding, recycling of moulding sands of a mechanical and thermal type, smelting in MF electric induction furnaces, shot blast systems, natural gas heat treatment furnaces, deburring machines and machining equipment based on CNC technology.

- Constant-temperature casting: Toshiba constant-temperature casting control system and patented filter screen provide a guarantee on constant-temperature casting.

- Strict quality control: Direct-reading spectrometers from Thermo Fisher and Barid are used to control the quality of our products in the manufacturing process.

- Health and safety is at the center of everything we do, from the daily routines in our plants to our customers’ project worksites.