Tie Rod Hydraulic Cylinder

Hydraulic Components, Hydraulics Parts

This kind of hydraulic cylinder is designed and manufactured in strict accordance of ISO6020/2 and DIN24 554 standards. According to different structure and working conditions of rods, this type cylinder has a highest working pressure of 21Mpa and satisfies most hydraulic projects that have high ISO or DIN standards. Our tie rod hydraulic cylinder establishes a well-respect reputation in the market thanks to a number of outstanding features, such as compact structure, light quality, high working efficiency, easy to assemble, convenient maintenance, good buffering device and flexible connecting method.

As for tie rod hydraulic cylinder, we can design and customize the piston rods, stroke, buffering device. The technical data are as follows.

- Available on 12 different mounting styles

- Piston rod of three specifications fitted with each cylinder bore

- Female and male threads on the piston rod end feature 3 specifications to fit with each cylinder bore

- A wide variety of accessories offered for the rod end of the cylinder

- Application-specific hydraulic cylinders customized to meet the most demanding application requirements

- Available on 5 different mounting styles

- Piston rod of two specifications fitted with each cylinder bore

- One male thread type on the piston rod end fitted with each cylinder bore

- Max working pressure: 210bar

- Inner diameter of cylinder: 25mm-200mm

- Diameter of piston rod: 12mm-140mm

- Type: Single rod or double piston rods type

- Stroke: Customized

- Buffering device: Either end or both ends

- Application: Five sealing methods are suitable for a wide range of oils

- Temperature range: -20℃-150℃ (Depends on properties of oil)

- Notes: If you have questions about our cylinder, please feel free to contact us. Our technicians will resolve your problems as soon as possible.

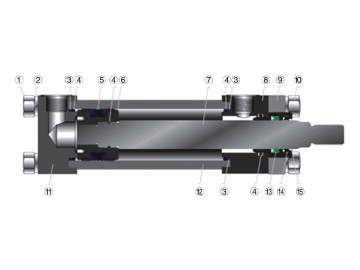

- 1. Tie rod

- 2. Spring washer

- 3. Locking ring

- 4. O-ring

- 5. Seal assembly

- 6. Piston

- 7. Piston rod

- 8. Cylinder head

- 9. Gland

- 10. Nut

- 11. Cylinder cap

- 12. U-ring

- 13. Cylinder tube

- 14. Dust ring

- 15. Guide sleeve

- Cylinder Tube

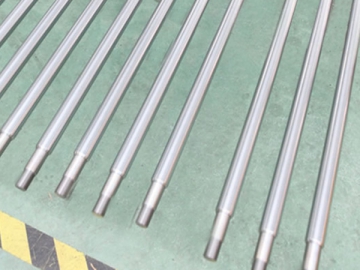

A smooth cylinder tube can protect the inner sealed parts in an effective way. That’s why each tube produced by Hoyo must undergo strict inspection and examination in order for a low roughness degree and friction coefficient. - Piston rod

Piston rod is made of high strength carbon alloy steel, and features a precision ground surface which is chrome-plated and polished to a 0.2 μm finish, significantly extending the service life of the gland seal. What's more, the piston rod surface is induction hardened before chrome-plating, achieving a surface hardness of higher than HRC54. The induction hardened piston rod boasts excellent impact resistance. - Detachable rod gland

The lipseal features a long bearing surface to retain oil for continuous lubricating, and can withstand high side loads. This greatly enhances the service life of the gland. The gland integrated with rod seals features a detachable design for quick maintenance and reduced cost. - Piston rod seal

Double-lip seal provides double sealing to act in turn as pressure increases. This ensures effective sealing under all working conditions. The serrations of the lipseal works as a check valve. When the piston rod retracts, the oil that is adhered to the surface of the piston rod is allowed to re-enter the cylinder.

Double lip sealing ring is used as a secondary seal, which can keep excess lubricating film in and help dirt out, greatly extending the service life of gland and seals.

Made of reinforced polyurethane, standard lipseals feature a service life up to 5 times that of traditional materials, providing efficient retention of pressurized fluid. Standard rod seals are suitable for speeds up to 0.5m/s. The special seals are available to meet the demanding applications.

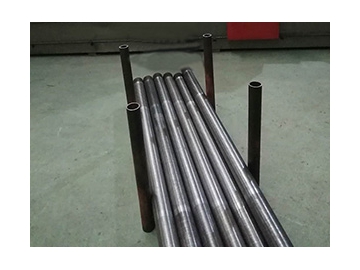

- Cylinder tube

The cylinder tube is manufactured with strict quality control standards and precision manufacturing technology, making the straightness, roundness and surface finish meet the demanding technical standards. After surface finishing, the friction on the interior surface of the cylinder tube is greatly reduced, significantly enhancing the seal life. - Cylinder seal

In order to get a better sealing, cylinder ends adopt a special design and a special ring. - One-piece piston

The one-piece piston features wear rings to resist side loading, and is well secured by both thread-locking compound and a locking pin. Four types of standard seal assemblies are available to adapt to different working conditions. - Cushioning

Designed with cushioning, the noise and shock loading can be greatly reduced, resulting in a faster cycle times and higher working efficiency. The cylinder speed can also gradually decrease due to the cushions at the cylinder head and cylinder cap. The cylinder head end cushion features a self-centering design. What's more, the polished cap end spear is an integral part of the piston rod. - Floating cushion bushes and sleeves

The excellent cushioning is achieved by the use of a floating cushion sleeve at the cylinder head end and a floating cushion bush at the cylinder cap end. - Cushion adjustment

Cartridge type needle valve is installed in both ends of the cylinder, and retained in the cylinder head and cap to avoid being accidentally removed. The cartridge type needle valve is suitable for the cylinders of up to 50mm bore. - Tie rod construction

A torque-load is applied to tie rod during assembly to generate a compressive force on the cylinder barrel, which offsets the tension caused by system pressure. Thus, a fatigue free hydraulic cylinder which features a long service life and compact structure is finally formed.

Cylinder tube

Cylinder tube Piston rod

Piston rod Assembly machine of seal rings

Assembly machine of seal rings