Superfine Impact Mill

Powder processing equipment for the production of battery cathode materials

Superfine impact mills are known for their ability to achieve ultrafine particle sizes with exceptional precision, making them an essential tool in the production of advanced materials. This particular mill is optimized for grinding critical battery materials such as lithium titanate, lithium iron phosphate, lithium manganese oxide, and lithium cobalt oxide, ensuring both efficiency and high-quality output.

This superfine impact mill is optimized for processing various battery materials, including lithium titanate, lithium carbonate, lithium hydroxide, and more advanced compounds like lithium iron phosphate and lithium manganese oxide. Its efficiency also extends to materials such as cobalt oxides and ferrous oxalate, ensuring precise and consistent results in high-performance applications.

- Capable of handling a broad range of feed sizes, supporting input particles up to 5mm in size, making it versatile for different materials

- Ensures precise particle classification, resulting in a consistently narrow and uniform particle size distribution

- Increases processing capacity by over two times compared to other classifiers, without additional energy consumption

- Reduces power consumption by up to 50%, making it an energy-efficient choice for large-scale production

- Enhances fine powder extraction by 50%, improving the overall efficiency of the classification process

- Incorporates a specialized sealing system, eliminating oversized particles and ensuring tight control over particle distribution

- Fitted with components that are protected with high-purity ceramics and wear-resistant coatings to prevent contamination and maintain product integrity

- Offers closed-loop air or nitrogen circulation options, ensuring low moisture levels and maintaining high purity standards based on material requirements

- Operates at reduced speeds while delivering fine powder output, significantly improving the stability of rotating parts and extending the lifespan of critical components by up to three times compared to conventional systems

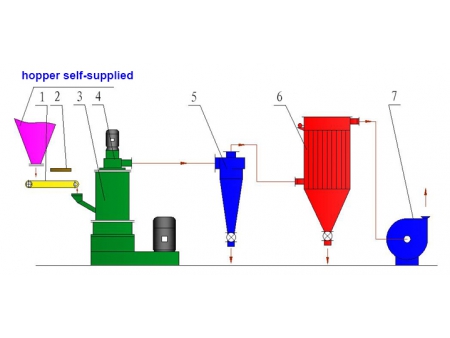

1. Material feeder

2. Metal separator

3. Grinding system

4. Classifying system

5. Cyclone separator

6. Bag filter

7. Draft fan