Impact Crusher

The impact crusher is able to crush mining ores with a high hardness and high abrasiveness, and can break hard rocks whose compression strength reaches 250Mpa. The impact crusher is mainly used for crushing lime rock, shale and other tough materials. It can be used with a roller feeder to form a special crushing system for crushing high hardness and abrasive materials.

| Specification | Maximum feed size(mm) | Discharge size(mm) | Production capacity(t/h) | Main engine power(kW) |

| 325 | 25-80 | 50~70 | 132 | |

| 325 | 25-80 | 90~145 | 132 | |

| 325 | 25-80 | 100~250 | 200 | |

| 325 | 25-80 | 280~320 | 400 | |

| 600 | 25-80 | 100~150 | 160-185 | |

| 600 | 25-80 | 180~220 | 355 | |

| 800 | 25-80 | 250~350 | 450 | |

| 800 | 25-80 | 350~400 | 500 | |

| 1000 | 25-80 | 450~650 | 710 | |

| 1000 | 28-80 | 600~800 | 800 | |

| 1500 | 25-100 | 800-1000 | 1250 |

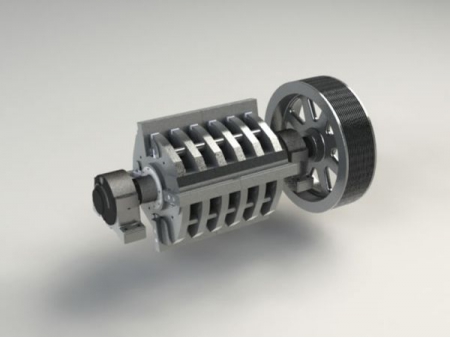

The impact crusher consists of the rotor, housing, impact plate, impact apron and driving part. The material particle size is determined by the gap between the bottom part of impact plate, the impact apron teeth plate and the rotor rotation circle.

Rotor

As the key part of the impact crusher, the rotor driven blow bar is used to hit material at a high speed until it is crushed.

Blow bar

The blow bar is made of highly abrasion resistant alloy material, and is capable of crushing large minerals.

Housing

All the parts of housing that come into contact with the material are protected by linear plates, with the gap between liners only 10mm. With a compact structure, assembly and disassembly is easily done.

Impact plate

There are two impact plates at the front and back of the impact crusher, which are designed to endure a high impact. The impact plate is designed with a cushioning adjustment structure in order to enhance the wear resistance.

Impact apron

The impact apron’s teeth plate is made of abrasion-resistant alloy and has a large crushing surface to crush highly abrasive materials. The gap between the plates can be adjusted to prevent materials from discharging too early.

- All wear parts of the impact crusher feature a high-usage and long working life. Sinomaly can provide a variety of spare parts according to customer requirements.

- The amount of sediment in raw materials is large during rainy seasons, and mud can easily block the crushing chamber. To prevent this, we recommend the use of pre-screening technology to separate fine materials and soil before crushing.

- The Sinomaly impact crusher is designed by making use of an impact crusher produced by HAZEMAG Company, thus ensuring it has a high degree of flexibility for abrasive materials.

- When crushing lime rock, the linear velocity of the blow bar is 30~40m/s, which is a suitable speed for crushing. This not only improves the production rate, but also ensure the final crushed product quality.