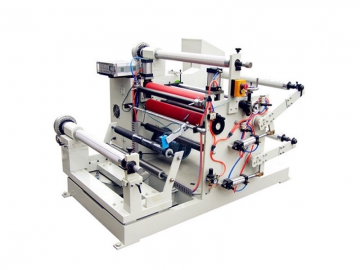

Slitter for Battery Materials Slitting and Winding of Battery Materials including Cathode, Anode Materials, Electrodes, Separator Films

Designed with servo motor, the rewinding and slitting machine features high precision, high stability, and low noise, which suits for slitting battery materials including cathode, anode materials, electrodes, separator films into narrow strips with desired width in a continuous manner. High production throughput, roll quality and yield can be greatly guaranteed in the battery manufacturing factory through using this battery material slitting machine. If you are a lithium battery manufacturer, our rewind slitting machine is your primary choice.

| Working voltage | 380V/50Hz |

| Power | 6kW |

| Compressed air | ≥0.6MPa |

| Guide roll width | 600mm |

| Slit materials | Battery materials including cathode, anode materials, electrodes, separator films |

| Unwinding shaft | Air expanding shaft, with automatic web guiding system |

| Max. roll diameter during unwinding and winding | 450mm |

| Edge burr | ≤15um |

| Automatic tension control | 0-25N (adjustable) |

| Alignment precision during unwinding | ≤±0.1mm |

| Slitting speed | 50m/min (adjustable) |

| Slitting widths | 25-600mm (upon request) |

| Slitting precision | ≤0.05mm |

| Circular blade | Outer diameter: 110mm Material: tungsten carbide powders Slitter knife holder: holds the blades precisely in place for slitting operation Slitter knife shaft: The slitter knife holder rotates with the knife shaft, enabling the blades rotates at a high speed to realize slitting operation. Notes: special tools available for quick installation and change for blades. |

| Winding shaft | Differential air shaft |

| Slitter edge curl | ≤ 0.1mm/m |

- Edge curl: results in a wavy edge at the slit which give the roll edge a wavy or shaggy appearance. This significantly influences the process precision throughout the battery manufacturing.

- Edge burr:Metal burrs may cause great damage to the lithium ion batteries. A short circuit between positive and negative terminals could happen due to the large metal burrs penetrating the battery separator film.

- Powder shedding:Powder shedding from the electrodes greatly reduces the battery performance, including reduced battery capacity and extraction of lithium-ion battery from the positive electrode.

-

Unwinding section

Details in Machine Components">- Air expanding shaft for unwinding

- Magnetic powder brake for constant tension control

- Web guiding system with photoelectric sensor

- Automatic detection and meter counting.

-

Winding section

Details in Machine Components">The differential air shaft is used for winding, ensuring equal tension on all rolls, synchronous roll running, and continuous slitting. The tension, slitting speed and air pressure can be easily set and clearly displayed on the touch screen.

-

Slitting system

Details in Machine Components">The slitting system is designed with a knife shaft setup cart. Various knife holders are available to adapt to varied slitting widths. The knife holders can be easily moved to the slitting machine for slitting operation after mechanical positioning. There is no need to adjust the slitting blades due to varied slitting widths. This greatly improves service life of the blade.

-

Automatic and precise control

Details in Machine Components">- Traction controlled by a servo motor

- Mitsubishi inverter control for winding

- PLC control system

-

Slitting

Details in Machine Components">Shear cut with rotary knives is specially suitable for slitting battery electrodes with intermittent coating. The slit electrodes feature smooth edge, without edge burrs and curl.

-

Designed with a dust collection system, the slitter dust during the slitting process can be efficiently removed, providing clean working environment. This also avoids contamination to the slit materials.

-

The support table is equipped for use during roll change, improving working efficiency.