Materials & Castings

Used in glass container and tableware manufacturing

Alloy Casting Materials

Our fully automated casting workshop produces high-quality alloy materials and castings to support the glass container and tableware industries. By combining advanced equipment with precise production techniques and affordability, we ensure alloy casting materials and moulds that meet the demands of modern glass manufacturing.

- Cast Iron: With an annual capacity of 8,000 tonnes, we produce casting materials such as vermicular graphite iron and ductile iron, ideal for castings, neck rings, guide plates, baffles, and blow heads.

- Cast Bronze: Our output of 2,000 tonnes includes various bronze alloys used for blow moulds, bottom plates, neck rings, and baffles.

- Stainless Steel: Using a secondary remelting process, this material is well-suited for precision tableware moulds, ensuring reliable performance.

- Nickel-Based Materials: Designed for demanding components like baffles, neck rings, and plungers, providing stability and longevity.

Our patented N2F castings material stands out for its exceptional properties, enhanced through solution strengthening. Compared to standard copper alloys, N2F offers improved thermal conductivity, strength, hardness, and stability. It is suitable for mould components such as blanks, neck rings, and bottom plates. Its exceptional thermal performance accelerates the glass bottle forming process, significantly improving production efficiency and meeting the demands of high-end manufacturers.

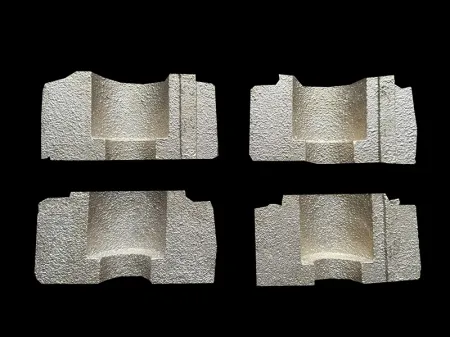

Castings

We provide high-quality castings to mould manufacturers worldwide, supported by advanced machining equipment, efficient production systems, and reliable logistics. These castings are designed to help clients achieve consistent quality, improve production efficiency, and stay competitive in a fast-paced market.