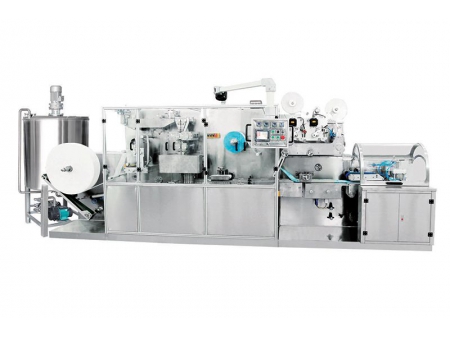

Fully Automatic Pocket Wet Wipes Machine

DC-2020B Wet Wipes Machine (5-30 pcs/pack)

Wet wipes machine integrating folding, wetting, stacking, packaging, labeling and sealing

Machine

- Production Speed 400-500 wipes per minute

- Design Speed 400-500 wipes per minute

- Fold Types Z-fold (cross folded)

Product

- Open Wipe Length 140-200mm

- Open Wipe Width 140-200mm

- Folded Wipe Length 140-200mm

- Folded Wipe Width 50-80mm

Designed for producing portable pocket-sized wet wipes, with adjustable production capabilities for 5-30 pieces per pack, this fully automatic wet wipe machine is perfectly suited for on-the-go convenience. This versatile machine can produce various types of wet wipes, including baby wipes, cosmetic wipes, specialty wipes, and cleaning wipes.

Featuring a single-lane production line integrating folding, wetting, stacking, packaging, labeling and sealing, the wet wipes machine is equipped with an easy-to-use human-machine interface for quick parameter settings. It offers simple operation, high stability, and efficient production speeds of up to 400-500 wipes per minute and 40-50 packs per minute (10 wipes per pack).

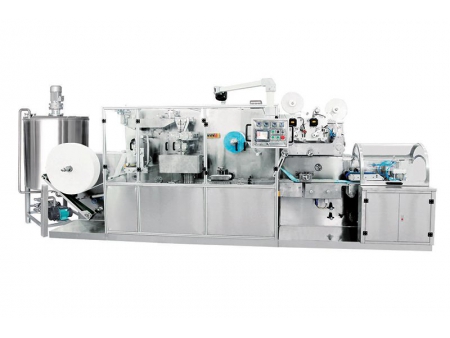

Built with Mitsubishi control systems, including Mitsubishi PLC and touchscreen controls, it ensures fully automated production, including calibration, cutting, folding, and packaging. With low maintenance costs and ease of operation, it effectively boosts wet tissue production efficiency, maximizing economic benefits for your business.

Automatic Unwinding → Synchronous Conveying → Longitudinal Folding → Wetting (Soaking) → Cut-Off and Cross Folding → Stacking and Counting → Automatic Packaging → Date Coding → Automatic Hole Punching → Automatic Labeling → Longitudinal Heat Sealing → Automatic Gusseting → Air Take-Out → Transverse Heat Sealing and Cut-Off → Finished Product

| Production speed | 400-500 wipes/min | Stack count | 5-30 sheet/stack |

| Design speed | 600 wipes/min | Stack height | Max. 50mm |

| Wipe material | Spunlace nonwoven fabric, wet-strength paper, thermal bond nonwoven fabric | Packaging material | PET/PE BOPP PET/AL/PE (heat sealing materials) |

| Material weight | 35-60g/m² | Number of wrapping film rolls | Wrapping film roll on 1 shaft (automatic splicing) |

| Number of parent rolls | Parent roll on 1 shaft | Wrapping film roll size | Width: ≤300mm Diameter: ≤350mm |

| Parent roll size | Width: 140-200mm Diameter: < 1200mm | Package size | Length: 120-330mm Width: 50-100mm Height: 10-50mm |

| Voltage | AC380V 50HZ three-phase five-wire | Label size | Length: 50-150mm Width: 30-80mm Roll diameter: < 350mm |

| Total power | 25kW | Label type | Clear label & non-clear label (dual-shaft labeling, simultaneous running or automatic switching) |

| Open wipe length | 140-200mm | Hole punching size | Length: 20-70mm Width: 15-50mm (hole punching and labeling at the same time) |

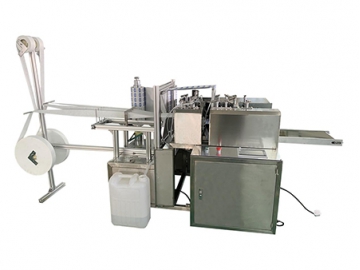

| Open wipe width | 140-200mm | Liquid adding tank | 600L×1 304 stainless steel tank with agitator (liquid level detector with alarm function) |

| Folded wipe length | 70-100mm | Air pressure | 0.6-0.8MPa |

| Folded wipe width | 50-80mm | Machine dimensions (L×W×H) | 5100×1320×2300mm |

| Fold type | Z-fold | Liquid tank size | 900×1900×1900mm |

| Fold format | Cross folded | Cutting length | 120-230mm (double blade cutting) |

| Wetting range | 2.5-5 times, soaking | Machine weight | Approx. 4.5t |

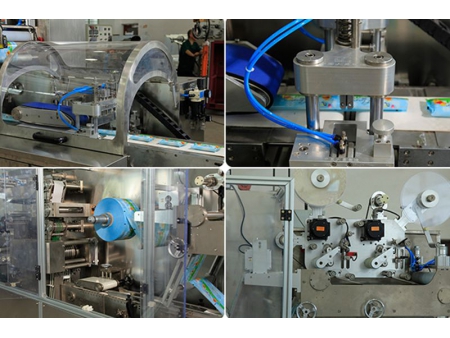

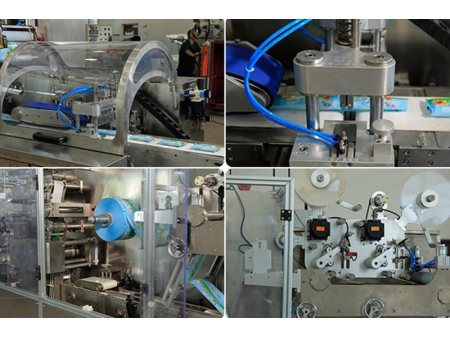

- Stainless steel frame, Mitsubishi electrical components.

- Electric differential gear, adjusting phase without stopping the machine.

- Synchronous transport of spunlace nonwoven fabric.

- Hole punching and labeling locations can be set via the touch screen.

- Reciprocating sealing device.

- Double labeling machines.

- The wet wipe machine automatically opens a window on the packaging films.

- Z,W,C folding styles.

- Spraying spunlace nonwoven wetting device.

- Roll folding at adjustable length.

- Spunlace cutting device.

- Spunlace lengthwise folding device.

- Spunlace widthwise folding device.

- Spunlace wetting device.

- Wet tissue cutting device, adopting high-speed steel cutting blade.

- Automatic counting and stacking device.

- Packaging film hole punching device.

- Packaging film forming device.

- Packaging film lengthwise sealing device.

- Packaging film widthwise sealing device.

- Closed gear box timing belt universal coupling.

- Stepwise labeling control.

- Variable frequency engine control.

- Independent servo control over stacking, pushing, and sealing to achieve synchronous operation.

- Spray extrusion control for lotion supply system.

- Coding device: ink coder with printing speed up to 300 beats / minute.