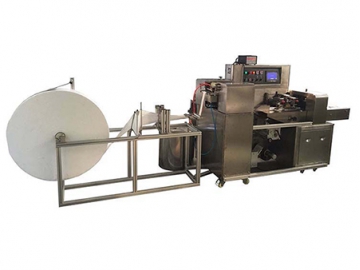

Fully Automatic Wet Wipes Packaging Machine

Request a Quote

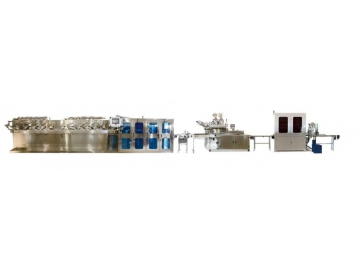

KGT-340D Wet Wipes Line (30-120 pcs/pack)

Wet wipes machine integrating packaging, labeling and sealing

Key Parameters

- Speed 45-65 packs/min

- Package Length 150-320mm

- Package Width 80-120mm

- Package Height 30-100mm

With an ensured performance precision and reliability, this fully automatic wet wipe packaging machine is tailored for efficient packaging of 30-120 pieces wet tissues per pack. Its intelligent control system and stable operation enhances the production efficiency while maintaining the highest standards of product quality and hygiene.

An ideal solution for modern wet wipe production, this wet wipes machine enables businesses to quickly meet market demands, gaining customer trust and satisfaction through consistent, high-quality results.

Wet Wipe Production Process

Automatic Unwinding → Date Coding → Automatic Hole Punching → Automatic Labeling → Color Mark Detection → Wipe Wrapping → Longitudinal Heat Sealing → Transverse Heat Sealing and Cut-Off → Finished Product

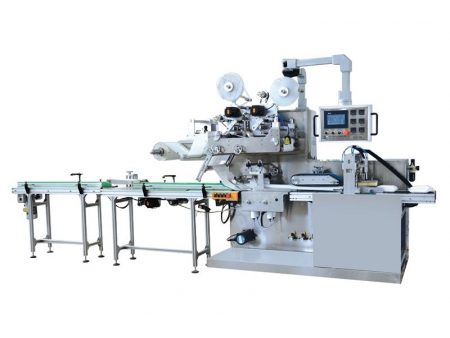

Specifications

| Packaging speed | 45-65 packs/min |

| Packaging material | PET/PE BOPP PET/AL/PE (heat sealing materials) |

| Material thickness | 0.06-0.1mm |

| Package size | Length: 150-320mm Width: 80-120mm Height: 30-100mm |

| Label size | Length: 50-150mm Width: 30-80mm Roll diameter: < 350mm |

| Label type | Clear label, printed lable, tamper evident label |

| Voltage | AC380V 50HZ three-phase five-wire |

| Total power | 11kW |

| Air pressure | 0.6-0.8MPa |

| Machine dimensions (L×W×H) | 4700×1200×2350mm |

| Machine weight | Approx. 3t |

Configurations

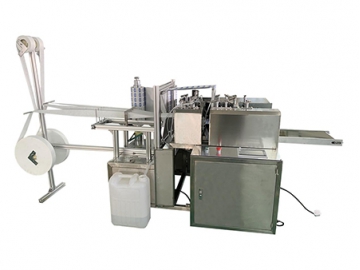

- Film unwinding unit: Single-shaft roll film with a diameter of up to 350mm, width of 420mm, and a 3-inch core diameter

- Photoelectric sensor system: Monitors for film breakage and low material levels

- Date coding device: Equipped with an ink roller coder for accurate date and batch coding.

- Die-cut unit: Standard 30x15mm die-cutting blade, customizable per client specifications.

- Dual label dispenser: Dual-shaft label applicators capable of simultaneous operation or automatic switching, synchronized with die-cutting for precise label placement.

- Adjustable packaging: Configurable to accommodate wet wipe widths between 80mm and 120mm, allowing for versatile packaging sizes.

- Heat sealing: Incorporates an adjustable cooling blower to cool and set tight the heat seal

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos