ATS Intelligent Engine Cooling System

Saiensi specializes in the research, development, and manufacturing of vehicle thermal management systems, with independent intellectual property rights and custom design capabilities.

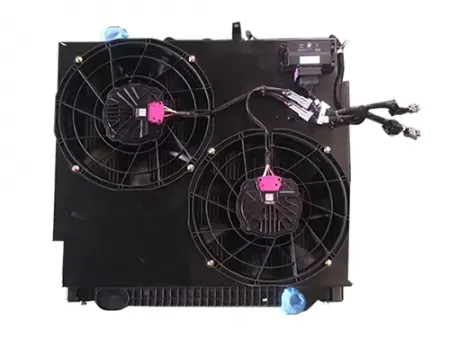

The ATS intelligent cooling system is a next-generation intelligent engine cooling solution that adopts electronic cooling fan technology, representing an upgrade from conventional engine cooling systems. It is widely applied in bus engines, commercial vehicle engines, and mining truck engines, providing efficient heat management and reliable performance in demanding environments.

Typically, the ATS intelligent cooling system is equipped with 1 to 8 electronic fans, configured according to the specific heat exchange requirements of each vehicle model. Based on customer needs and vehicle cooling capacity, our company provides targeted development and integration solutions.

The ATS intelligent cooling system offers a fully integrated solution combining automatic power switching control with intelligent on-demand thermal management. Through the monitoring and switching functions of ATS, the system automatically activates and adjusts cooling operations to achieve efficient heat dissipation, energy savings, noise reduction, extended component lifespan, and enhanced system reliability.

This technology has become increasingly common in modern high-performance combustion engines, turbocharged vehicles, hybrid models, and electric vehicles, serving as a core technology for improving overall vehicle performance, durability, and efficiency.

- Cooling performance: Compared with conventional cooling modules, heat dissipation performance is increased by over 30%.

- Insulation performance: The radiator body and frame maintain insulation resistance above 20 MΩ under 1000V, ensuring safety under high-voltage operation.

- Electrical conductivity: After standing for 90 days, the system maintains conductivity below 3.0 μS/cm; after exposure to 85°C for 48 hours, conductivity remains below 5.0 μS/cm, a level unattainable for ordinary radiators.

The ATS intelligent cooling system is composed of

- Cooling components: Radiator, intercooler, etc.

- Circulation components: Water pump, fan, coolant pipe.

- Control components: Thermostat, temperature sensor.

Saiensi produces aluminum automotive radiators, an essential component of the engine cooling system. The radiator dissipates heat from the coolant as it passes through the radiator core, effectively lowering the engine’s temperature and ensuring stable operation within the optimal working range.

Saiensi specializes in the production of vehicle thermal safety management products, supported by a CNAS-certified professional laboratory and an 80% in-house manufacturing rate. This ensures strict and precise control over materials, cost, delivery, and product quality.

Radiators are available in two configurations: plate-fin radiators and finned tube radiators, each optimized for different cooling applications.

| Comparison Between Plate-Fin and Finned Tube Radiators | ||

| Item | Plate-fin (vacuum brazing) | Finned tube (N₂–O₂ protective brazing) |

| Structure | Enclosed vacuum furnace with high sealing requirements | Open continuous aluminum brazing furnace under protective atmosphere |

| Brazing material | Magnesium-containing alloy | Newly developed ion-free alloy |

| Strength/ quality | High brazing strength (~30 MPa), reliable cleanliness | Moderate strength (~3 MPa), minimal flux residue |

| Production efficiency | Low (8 hours per furnace, 30–60 units per batch) | High (continuous brazing, 200–300 units per shift) |

| Thermal performance | Moderate efficiency: e.g., 170 kW (core 1000×1000×110 mm, ΔT = 40°C, 230 L/min) | High efficiency: e.g., 180 kW (core 1000×1000×56 mm, ΔT = 40°C, 230 L/min) |

| Weight | Larger and heavier (~60 kg, 1200×1000×120 mm) | Compact and lightweight (~25 kg, 1200×1000×56 mm) |

| Production cost | Higher cost, lower yield, higher labor input | Lower cost, higher productivity |

| Conductivity control | < 5 μS/cm after 24-hour stabilization | < 3 μS/cm after 24-hour stabilization |

| Insulation resistance | Independently developed: the radiator core and outer frame are required to maintain an insulation resistance greater than 20 MΩ under a 500 V test voltage; actual testing shows an insulation resistance of 5.5 GΩ at 500 V. | |