Rubber Strainer

Our rubber strainer utilizes piston extrusion and conveying mechanisms to effectively eliminate impurities from rubber compounds and recycled rubber. Comprising essential components such as the plunger, barrel, filter head, and transmission device, our rubber strainer offers efficient filtration.

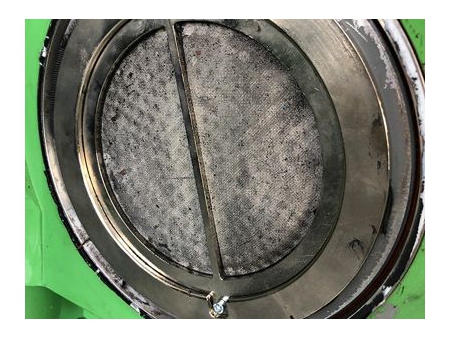

Equipped with a perforated plate and filtering mesh, the filter head supports the filtering process, ensuring consistent and reliable impurity removal. Our rubber strainer operates without generating excess heat, preventing undesirable burning during the filtration process.

Our rubber strainer is suitable for a wide range of rubber materials, including nitrile rubber, butyl rubber, fluoro rubber, silicone rubber, and more. With filtration precision reaching up to 300 mesh, our rubber strainer meets the stringent demands of various rubber processing scenarios.

| Model | | |

| Barrel Diameter (mm) | 200 | 250 |

| Max. Operating Pressure (Mpa) | 24 | 24 |

| Batch Size (L) | 20 | 40 |

| Max. Barrel Temperature (℃) | 95 | 95 |

| Filtering accuracy (mesh) | 40-300 | 40-300 |

| Total Power (kW) | 16 | 19 |

| Weigh (kg) | 2800 | 3800 |

| Dimensions (L*W*H) (mm) | 3000*1100*1750 | 4000*1100*1750 |

- Eliminates heat generation and burning issues commonly associated with screw filtration systems.

- Hydraulic proportional controller with electronic modules maintains consistent pressure, ensuring stable extrusion speed and pressures up to 5500 psi.

- Chromium-plated alloy extrusion barrel guarantees dimensional stability even under high temperatures, friction, and vacuum conditions, ensuring precise extrusion volume and quality.

- Temperature control through digital display ensures consistent strainer head and barrel temperatures.

- Incorporates imported Omron electrical components and pressure differential display for accuracy and reliability. Additionally, the extrusion device can function as a piston extruder for filtering and producing rubber strips.

This straining system consists of a plunger, barrel, filter head, and transmission device, among other parts.

The filtration precision of our rubber strainer is up to 300 meshes.