Horizontal Sand Mill

As the first wet grinding equipment in the market, the horizontal sand mill is widely used for the lapping of materials in ink, paint, coating, pesticide and other industries. Particles with the desirable fineness can be obtained after a short time. Easy to operate and convenient to maintain, this equipment has good reliability and high efficiency, which can meet the needs of customers.

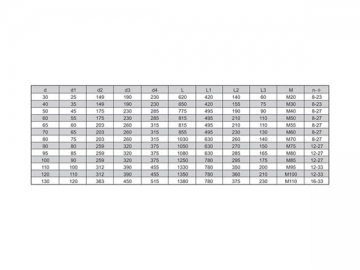

Specifications| Mode | MYM15A | MYM20A | MYM30A | MYM48A | MYM60A |

| Tank Volume (L) | 15 | 20 | 30 | 48 | 60 |

| Motor power (KW) | 11 | 18. 5 | 22 | 37 | 45 |

| Production Capacity (kg/h) | 30-200 | 40-300 | 50-600 | 100-1000 | 150-1200 |

| Fineness (μm) | 2-20 | ||||

| Pump Type | Diaphragm pump/Gear pump | ||||

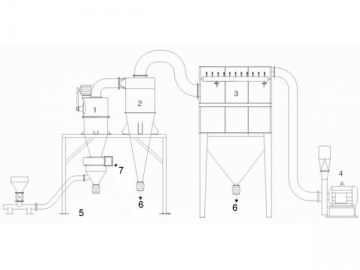

Strong collision and friction among grinding media are caused by the dispersing discs, so materials are ground and dispersed efficiently. Adopting the optimally designed mechanical seal, this horizontal sand mill is reliable and durable. It is equipped with cooling liquid compatible with the grinding material, which can reduce the pollution to the grinding material. Better grinding effect can be achieved by adopting zirconia beads and grinding disc with better strength. The grinding cylinder employs spiral water-cooling technology which has good cooling effect.

As a professional horizontal sand mill manufacturer and supplier in China, we provide a vast array of products that includes agitated bead mill, steam heating reactor, Reactor Using Mechanical Seal, fluidized bed jet mill, and more.

Related Names

Sander | Bead Mill | Horizontal Sanding Mill