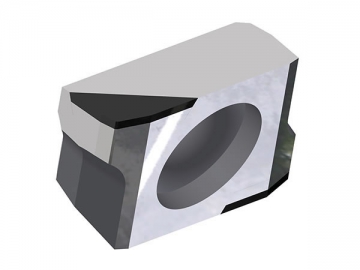

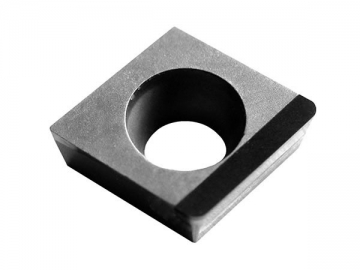

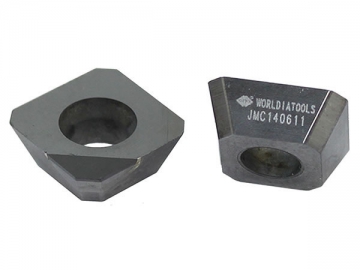

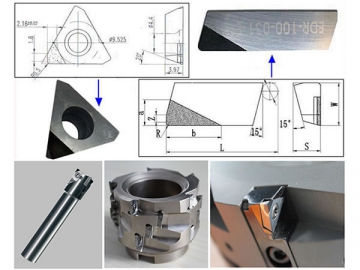

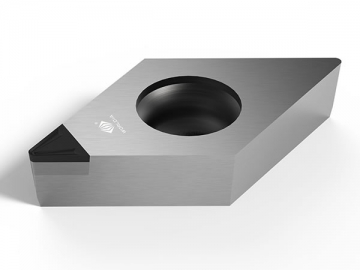

PCD Milling Insert

Description

PCD(Poly Crystal Diamond) refers to diamond particles which have been sintered together with a binder phase under high pressure, high temperature conditions similar to those used in single crystal diamond synthesis. These sintered PCD materials have a variety of uses, most notably for cutting tools, machining non-ferrous metals, non-metallic materials and wear parts.

As cutting tool material, PCD is generally recommended for the machining non ferrous workpiece which high abrasion resistance is required.

| Materials to be Processed | Products | |

| Nonferrous Metal | Aluminum, Aluminum Alloy | Piston, cylinder, wheel hub, transmission case, pump body, admission pipe and various shell parts for cars and motorcycles. |

| Tank body, shell and compressor parts for airplanes and electro mechanical products. | ||

| Precision machinery parts for cameras, duplicators and metrical instruments. | ||

| Parts for pump body and oil press. | ||

| Copper, Copper Alloy | Axle, bearing bush, bearing and pump body for internal combustion engines and ships. | |

| Parts for various instruments, dynamo commutators, printed boards and electronic apparatus. | ||

| Bearing, bearing bush, valve and shell body. | ||

| Tungsten Carbide | Sinter such as valve seat and cylinder, and semi-finished sinter. | |

| Others | Various nonferrous metal parts such as magnesium and zinc. | |

| Nonmetal | Wood | Hardwood, artificial board, artificial abrasion resistant fiberboard. |

| Reinforced Plastic | Glass fiber and carbon fiber reinforced plastic. | |

| Rubber | Roller for paper and rubber ring. | |

| Graphite | Carbon rod. | |

| Ceramic | Sinter such as sealing ring and plunger piston, and semi-finished sinter. | |

Features of PCD Milling Inserts

PCD milling insert has advantages of long service life, high processing efficiency, high surface roughness, and high machining accuracy, which compared to alloy cutting tools and natural diamond tools.

1. This diamond cutting tool is used for processing non-ferrous metals, the surface roughness reaches Ra0.1 above, which is close to the mirror effect.

2. Wide range of cutting materials improves the production cycle, and make the PCD tipped insert processing more parts.

3. Cutting speed and feed rate were significantly accelerated, compared with the traditional cutting tools.

4. The workpiece quality is greatly improved, the size control is excellent, the accuracy of the surface is consistent, the rejection rate is reduced.

5. The PCD milling insert has long service life, the production capacity has greatly improved.

Material

The tool bit uses PCD blanks manufactured by world famous companies.

The body part uses high quality tungsten carbide.

Application

The PCD milling insert can be used for turning operation in many fields including aerospace, car industry, energy equipment, and the wood and stone industry. It also can be used to finish machining different materials such as nonferrous metal, tungsten carbide, ceramic, reinforced plastic, rubber nonmetal and composite material.

Packaging

The PCD milling inserts uses plastic case for packing.

Quality Control

We have dedicated team of quality control and precise equipment to keep good and stable performance for our products and processing services.

OEM/ODM Service

We can customize the cutting tool and laser markings as per required. Our business partners are all over the world including some cutting tool industry giants.

As a specialized PCD inserts manufacturer and supplier in China, Worldia also provides a wide range of products including diamond engraving tool, PCD saw blade, PCD diamond scribing wheel, and much more.