Rotogravure Printing

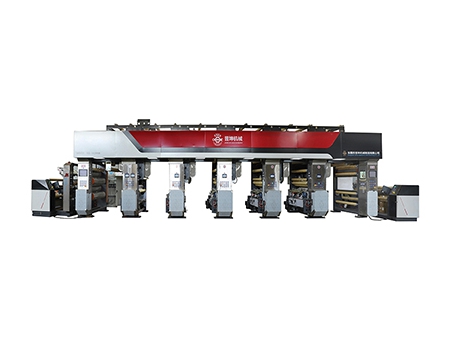

Our rotogravure printing press is a high performance piece of equipment that can print up to 7 colors with a maximum width of 1000mm, circumference of 900mm, and with a printing precision up to +/-0.15mm.

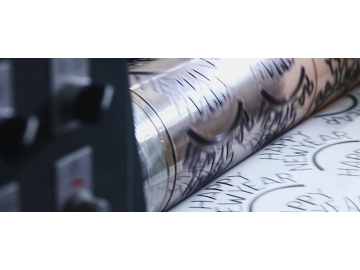

High quality rotogravure printing is capable of applying a thick ink print, raised printed images, rich layers, clear lines, and vivid colors. The cells which are made according to the original image are filled with ink and the line thickness and ink layer are adjustable. This makes the printed products much more difficult to imitate or forge, especially when combined with different cell depths.

DGJS applies highly automated equipment to achieve high quality printing with excellent precision of 120 DPI. This is also a simpler process than offset printing.

Rotogravure printing is a high-cost, but durable printing method, so it is most often used for high volume printing jobs. The higher the printing quantity, the better the efficiency.

Most soft materials are suitable as printing substrates with this type of printing. This includes plastic, paper sheet, aluminum foil, and self-adhesive paper. There are some substrates like textiles that are flexible and stretchy that are most effectively printed with rotogravure printing compared to flexo and offset printing.

DGJS has adopted new water-based and alcohol soluble inks that are designed to meet environmental protection standards for more eco-friendly printing.