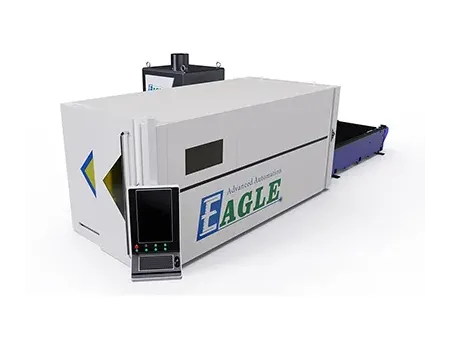

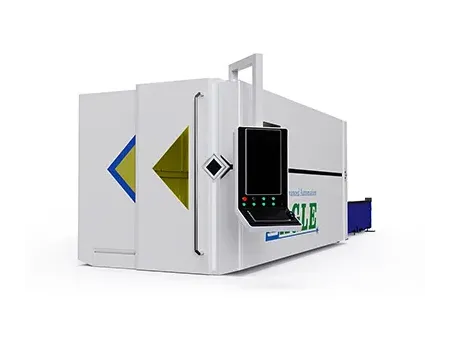

Enclosed Flatbed Fiber Laser Cutting Machine

The enclosed flatbed fiber laser cutting machine is designed for high-speed cutting of various metal sheets. It provides a reliable solution for ultra-fast production, meeting the demands of large-format, high-volume, and high-efficiency sheet metal processing. The laser cutting machine is widely used for high-precision cutting of materials such as carbon steel, stainless steel, tinplate, galvanized sheet, aluminum, and copper. With a laser head acceleration of over 1.0G and a working area of 5′×10′, the laser machine comes equipped with nesting software to optimize material usage and minimizes waste, ensuring that production is both efficient and cost-effective. It is available in 6kW, 12kW, or 20kW models, capable of cutting stainless steel thicker than 2 inches.

-

- Laser cutting of carbon steel workpiece

-

- Laser cutting of brass jewelry

-

- Laser cutting of stainless steel nameplate

-

- Laser cutting of carbon steel part

| Model | LF-1530 |

| Laser Power | 12000W |

| Working Size | 1500×3000×100mm |

| Metal Sheet Size | 1500×3000×100mm |

| Max. Speed | 80m/min |

| Max. Acceleration | 1.2G |

| Positioning Accuracy | ±0.05mm/m |

| Repeatability | ±0.03mm/m |

| Max. Material Loading | 1760kg |

| Machine Weight | 3500kg |

| Dimensions | 3430×5130×2290mm |

| Power Supply | 3P, 380V±5%, 50Hz |

| Power Consumption | ≤25kW |

| Max. Cutting Thickness | |

| Carbon Steel | 35mm |

| Stainless Steel | 25mm |

| Aluminum | 20mm |

| Copper | 8mm |

| Brass | 12mm |

- Laser cutting head

The flatbed laser cutting machine is equipped with a precision fiber laser cutting head specifically designed for high-quality cutting. It features an advanced mechanical structure and high-quality collimating and focusing lens. The laser cutting head includes collision protection, ensuring the highest level of process reliability. Real-time sensors monitor the lens for perforation, cutting quality, edge quality, and overall status of the operation, ensuring a smooth and reliable cutting process.

- Laser Source

The 6000W-20000W high-power continuous wave multimode laser source is water-cooled and modularly designed. This laser source is compact, highly integrated, maintenance-free, and offers high reliability with excellent beam quality and stability.

- Accurate Motion System

The power system is driven by imported servo motors, combined with a high-precision rack and pinion transmission and guided by imported linear guides. This setup enables high-speed, high-precision motion with excellent responsiveness and stability.

- Water Chiller

A high-quality industrial water chiller is equipped in the laser cutting machine, ensuring the fiber laser always receives optimal cooling. This maintains consistent output performance and stability during long continuous operation.

-

Our industrial laser cutting machine is designed with user convenience and flexibility in mind. Hardware and software are integrated into a complete, ready-to-use package with numerous features that enhance usability and profitability.

-

The lightweight gantry, combined with durable guide rails, transmission racks, and high-performance servo motors, ensures the machine can perform cutting at exceptionally high speeds.

-

The laser cutting machine is enclosed in a protective housing, providing maximum safety during operation.

-

The laser machine is designed with interchangeable working beds for efficient loading and unloading during the cutting process.

-

The multi-chamber exhaust system efficiently removes smoke and suspended particles, maintaining a clean working environment.

Fiber laser cutting machines are typically used to cut various metals, while CO₂ laser cutting machines (such as X1309) excel in cutting wood and acrylic items.

A laser engraving and a laser cutting machines are essentially the same type of equipment. The main differences lie in their power, available accessories, and the wattage of the laser system. The most suitable laser machine depends on the primary application and the material to be processed.