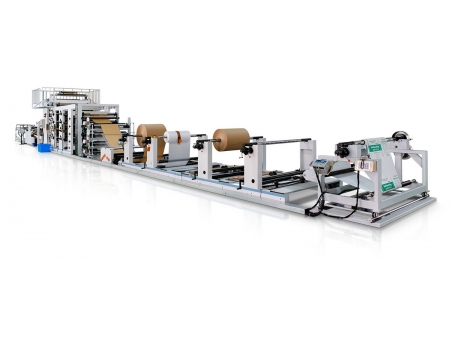

Valve Sack Tuber (Flush Cut), YR2019

YR2019 valve sack tuber is mainly designed for the production of kraft valve sacks, such as hot-melt glue sealing paper valve bag and ultrasonic sealing paper valve bag. It employs flush cut as the type of cutting, allowing customers to make pasted valve sacks with either graduated or straight-out cut ends.

Moreover, our valve bag tuber can be paired with valve sack bottomer to make kraft paper bags of 500-1100mm in length, 350-620mm in width and up to 80mm of bottom width. The produced valve sacks can be used widely to hold powdered and particulate substances, such as cement, mortar, chemical materials and food.

- Kraft valve sack

- Kraft valve sack

- Hot-melt glue sealing paper valve bag

- Ultrasonic sealing paper valve bag

| Length | 500-1100mm |

| Width | 350-620mm |

| Bottom Width | ≤80mm |

| Maximum productivity | 150 sacks/min |

| Layers | 2-3 layers of paper 1layer of film |

| Size | 30.5×2.8×2.7 m |

| Weight | 25 t |

| Type of cutting | Flush cut |

- Unwind station

- Web guide

- Assisting traction unit

- Transverse perforation unit

- Transverse adhesion unit

- Longitudinal adhesion unit

- Forming unit

- Valve bag discharging unit

- 4 color in-line printer

- Intermittent perforation unit

- Main traction flush-cut unit

- Center sealing extrusion unit

Youniker offers both complete line and individual equipment including valve sack tubers and bottomers to satisfy your paper bag production needs.