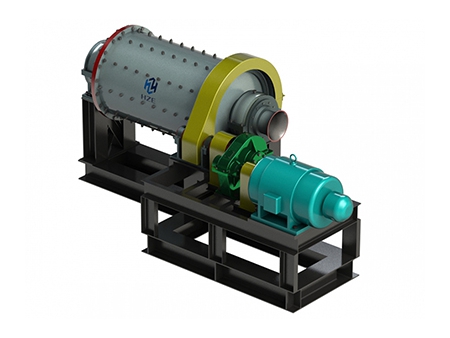

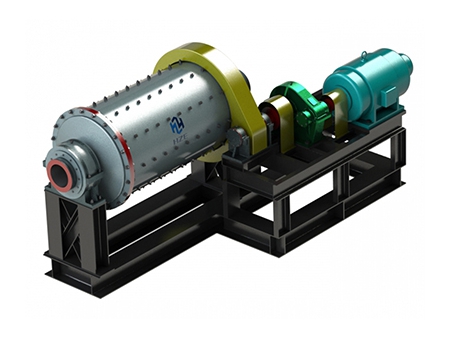

Rod Mill

The rod mill is an ore grinding equipment with a number of loose steel rods inside.

Working Principle

The transmission device drives the shell to rotate. After the materials and water are fed into the feeding end, the size of the materials is reduced by the impacts of the steel balls and ores that drop from the feeding end. The continuous feeding compels the materials to move from the feeding end to the discharge end. The ore slurry will flow out of the outlet when the slurry level is higher than the lower edge of the discharge trunnion.

- The rod mill's heads with a big cone angle can make the steel rods move regularly in the shell, preventing the rods fighting against each other.

- The discharge trunnion with a large diameter makes maintenance easy and enables rapid discharge of the slurry by maintaining the slurry level at an appropriate level.

- Identical particle size and rare excess grinding.

The rod mill is mainly used for preliminary grinding. The processing equipment is suitable to crush and grind ores in the first grinding phase, especially to process brittle materials.

As one type of the most common mining equipments, ball mills are widely used in mineral processing, construction and chemical industries and for acquiring silicate and other processed ores. In general, the ball mills are used by small, medium and large-sized mineral processing companies to crush and grind ores, including gold, silver, copper, lead, zinc, nickel, manganese, iron and molybdenum, as well as limestone, barite, quartz, graphite, feldspar and fluorspar.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Power (kW) | Effective Volume (m3) | Max. Rod Load (t) |

MBY0918 | 900 | 1800 | Y225M-8 | 22 | 0.9 | 2.4 |

MBY0924 | 900 | 2400 | Y250M-8 | 30 | 1.2 | 3.2 |

MBY1224 | 1200 | 2400 | Y280M-8 | 45 | 2.28 | 6.2 |

MBY1530 | 1500 | 3000 | JR125-8 | 95 | 5 | 13.5 |

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Power (kW) | Effective Volume (m3) | Max. Rod Load (t) |

MBYg2130 | 2100 | 3000 | JR136-8 | 180 | 9 | 24.3 |

MBYg2136 | 2100 | 3600 | JR137-8 | 210 | 10.8 | 29.2 |

MBYg2430 | 2400 | 3000 | JR138-8 | 280 | 11.5 | 31.1 |

MBYg2732 | 2700 | 3200 | JR157-8 | 320 | 15.7 | 42.4 |

MBYg2736 | 2700 | 3600 | JR1512-8 | 380 | 17.7 | 47.8 |

MBYg2740 | 2700 | 4000 | TDMK400-32 | 400 | 20.4 | 55.1 |

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Power (kW) | Effective Volume (m3) | Max. Rod Load (t) |

MBY3040 | 3000 | 4000 | JR157-8 | 440 | 26 | 70.2 |

MBY3245 | 3200 | 4500 | TDMK800-36 | 800 | 31 | 83.7 |

MBY3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 41.8 | 112.9 |

MBY3654 | 3600 | 5400 | TDMK-1600 | 1600 | 49.7 | 134.2 |