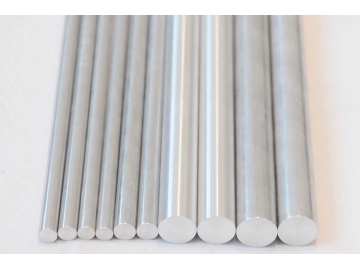

Aluminum Bars and Rods

With outstanding dimensional tolerances, machinability, and grain structure, Goldex’s extruded aluminum bars and rods are ideal for high demand applications, including aircraft rivets, earphone housings, auto piston skirts, camera accessories and more. The tolerances and dimensional accuracy of these aluminum bars is improved through subsequent cold drawing processes.

As an established ASTM, EN, and JIS certified manufacturer of aluminum bars and rods, Goldex is dedicated to carrying out production in accordance with the highest quality control standards and methods. Each batch of materials will be inspected with an optical emission spectrometer and metallurgical microscopy, ensuring they are qualified. We also have homogenization heat treat system, ensuring good mechanical properties of aluminum alloy products.

We offer these aluminum bars and rods in a wide array of different diameters and shapes, including customized shapes and sizes. Most aluminum grades are available, covering everything from the 1,000 series to the 7,000 series of aluminum. It is our mission to offer the right aluminum bar options to meet your needs. The following guides offer more information about our dimensional ranges.

| Item | ||||||

| technology | extruded | drawn | extruded | drawn | extruded | drawn |

| outer Min | 8mm | 7mm | 8mm | 7mm | 8mm*8mm | 7mm*7mm |

| outer Max | 122mm | 122mm | 120mm | 110mm | 120mm*120mm | 110mm*110mm |

1. Engine piston skirts: 4000 series Al-Si alloy such as 4032/4Y32 is ideal for manufacturing engine piston skirts due to its excellent abrasion resistance and low expansion coefficient.

2. Lead-free quick cut bars: These are made of GE6618 or GE6626 aluminum alloy and feature an excellent cutting performance and excellent cutting surface. GE6618 or GE6626 aluminum alloy is commonly used to manufacture car parts and fasteners such as screws and bolts for the electronic and electrical industries.

3. Car suspensions and swing arms: These are primarily made of 6082 aluminum alloy, which features an excellent weldability, cold workability and formability, excellent corrosion resistance, and medium strength.

4. Office equipment flanges: These use 2017 aluminum alloy thanks to its high dimensional accuracy and moderate hardness, making the 2017 aluminum alloy suitable for precision machining using CNC precision automatic lathes.

| Grade | Temper | Application |

| 1070 | H112 | Aluminum foil,capacitor,cable cover,ornament |

| 2011 | T3, T8 | Machined products that require an excellent machinability such as rivets |

| 2014 | T4.T4511 | Parts with high strength and high hardness(including in high temperatures)requirements,such as wheels,truck frames and suspension parts |

| 2014A | T6.T6511 | |

| 2017 | T4 | Electric parts for automobiles,engine management systems |

| 2017A | T4.T4511 | Universal mechanical parts,rivets,traffic and building structural components |

| 2024 | T3, T3511 | Truck wheels,airplane structural components and other structural components |

| 3003 | O | Parts that require a high corrosion resistance or good weldability,such as energy storage system shells for new energy automobiles |

| H112 | ||

| 3004 | H112, O, H34, H32, H36 | Printer drum, beverage can |

| 3304 | H112, O, H34, H32, H36 | Lamp parts |

| 4032 | F, T6, O | Automotive piston, fixed and moving plates for air conditioners, and heat-resistance parts |

| AHS | ||

| 5052 | H112, H32, H34, O | Camera housing, transportation and ship stamping parts |

| 5056 | ||

| 5083 | H112 | Ship and automobile welding |

| O | ||

| 6005 | T1, T5, T6 | Ladder and television antenna |

| 6101 | T6 | Electric conductor,heat abstractor,high strength bars used in bus |

| 6A02 | T4, T451, T6, T6511, T6510, O, F | Forgings with complicated shapes and airplane engine parts |

| 6061 | T6, T8, O, F | Shock absorber for automobiles,charging connectors for new energy vehicles,high-voltage wire connectors |

| 6063 | T4, T5, T6 | Structural components for automobiles, ships, airplanes and light industry |

| 6066 | O, T4, T42, T6, T62, T6511, T6510 | Welded structural components and forgings |

| 6463 | T4, T5, T6 | Automotive finishing components with a bright surface after anodizing |

| 6013 | T4, T6, O | Baby carriage frames |

| 6020 | T6, T8, O | Engine nozzle parts |

| 6082 | T6 | Automobile suspension arms,automotive instrument panels |

| 7005 | T6 | Car truss, bar, large heat exchanger and sports equipment, such as tennis rackets,baseball bats |

| 7020 | T6 | Aerospace structural components and automobile welding |

| 7050 | T6, T6511, T76, T73, T7351 | Sports equipment including ski poles, baseball bats, alpenstock |

| 7075 | T6, T6511, T76, T73, T7351 | Airplane structural components and other high stress structural components,sports equipment |

Get in touch with us