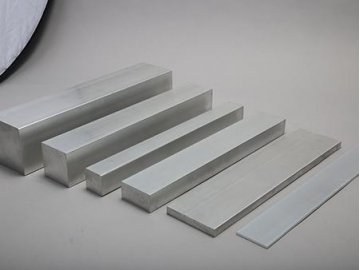

Aluminum Plates and Sheets

Goldex carries a variety of aluminum plates and sheets used for aircraft panels, engine parts, electronic enclosures, and more. Each of our aluminum products is manufactured using an indirect extrusion process, which reduces frictional heat and ensures a higher production efficiency and more consistent dimensions.

Equipped with 4 extrusion presses and other in-house facilities, we offer an extensive array of aluminum plates and sheets, available in just about all common aluminum grades and alloys, from the 1,000 to the 7000 series, offering customers the best material selection.

We carry out production in accordance with a strict quality control system based on ISO9001 and IATF16949 standards. All raw materials are inspected using an optical emission spectrometer and metallurgical microscopy to ensure the quality. During the melting and casting process, we use a nitrogen degassing unit and homogenizing heat treatment equipment to ensure a better grain structure and mechanical properties in the aluminum products. Prior to final delivery, we carry out extensive testing and inspection, including eddy-current, ultrasonic inspection, tensile testing and hardness testing.

Our aluminum plates and sheets can be cut-to-size to fit your needs and shipped directly to you. Specific dimensional ranges can be found below.

| 10 | 12 | 13 | 15 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |

| 10 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 12 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 13 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 15 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 18 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 25 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 30 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 35 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 40 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 60 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 70 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 80 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 90 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 110 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

Perpendicular: Diameter in mm, Horizontal: Wall thickness in mm

1. Consumer electronic shells: These are often made of 5052/6061/7000 aluminum alloy as it features an excellent processability, bright finished surface after anodizing, a gorgeous metal texture and rich color. The 5052/6061/7000 aluminum alloy is widely used in manufacturing mobile phone shells, tablet shells, smart home items, audio equipment and more.

2. Car dashboard: The car dashboards are made using 6082 aluminum alloy as it features an exceptional processability, medium strength, and high dimensional accuracy.

| Grade | Temper | Application |

| 1070 | H112 | Aluminum foil,capacitor,cable cover,ornament |

| 2011 | T3, T8 | Machined products that require an excellent machinability such as rivets |

| 2014 | T4.T4511 | Parts with high strength and high hardness(including in high temperatures)requirements,such as wheels,truck frames and suspension parts |

| 2014A | T6.T6511 | |

| 2017 | T4 | Electric parts for automobiles,engine management systems |

| 2017A | T4.T4511 | Universal mechanical parts,rivets,traffic and building structural components |

| 2024 | T3, T3511 | Truck wheels,airplane structural components and other structural components |

| 3003 | O | Parts that require a high corrosion resistance or good weldability,such as energy storage system shells for new energy automobiles |

| H112 | ||

| 3004 | H112, O, H34, H32, H36 | Printer drum, beverage can |

| 3304 | H112, O, H34, H32, H36 | Lamp parts |

| 4032 | F, T6, O | Automotive piston, fixed and moving plates for air conditioners, and heat-resistance parts |

| AHS | ||

| 5052 | H112, H32, H34, O | Camera housing, transportation and ship stamping parts |

| 5056 | ||

| 5083 | H112 | Ship and automobile welding |

| O | ||

| 6005 | T1, T5, T6 | Ladder and television antenna |

| 6101 | T6 | Electric conductor,heat abstractor,high strength bars used in bus |

| 6A02 | T4, T451, T6, T6511, T6510, O, F | Forgings with complicated shapes and airplane engine parts |

| 6061 | T6, T8, O, F | Shock absorber for automobiles,charging connectors for new energy vehicles,high-voltage wire connectors |

| 6063 | T4, T5, T6 | Structural components for automobiles, ships, airplanes and light industry |

| 6066 | O, T4, T42, T6, T62, T6511, T6510 | Welded structural components and forgings |

| 6463 | T4, T5, T6 | Automotive finishing components with a bright surface after anodizing |

| 6013 | T4, T6, O | Baby carriage frames |

| 6020 | T6, T8, O | Engine nozzle parts |

| 6082 | T6 | Automobile suspension arms,automotive instrument panels |

| 7005 | T6 | Car truss, bar, large heat exchanger and sports equipment, such as tennis rackets,baseball bats |

| 7020 | T6 | Aerospace structural components and automobile welding |

| 7050 | T6, T6511, T76, T73, T7351 | Sports equipment including ski poles, baseball bats, alpenstock |

| 7075 | T6, T6511, T76, T73, T7351 | Airplane structural components and other high stress structural components,sports equipment |