Extruded Aluminum Tubing, Drawn Seamless Aluminum Tubing

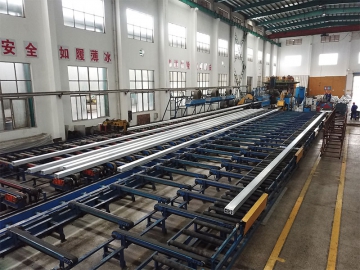

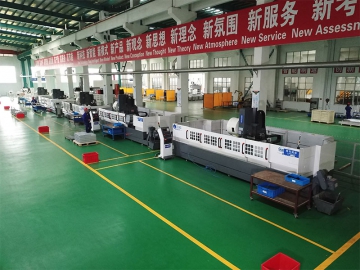

We offer seamless aluminum tubes and tubing based on advanced indirect extrusion technology. Our facilities are equipped with numerous extrusion presses to produce tubes in a wide array of dimensions, and after extrusion, a subsequent cold drawing process ensures a precise final dimension and high mechanical strength for all aluminum tube. This enables us to offer aluminum tubes with smaller diameters and thinner wall thicknesses. Annealing and quenching are available to increasing hardness and increase ductility if necessary. We also offer cut to length services with a high tolerance and exceptional measurement accuracy to meet your needs.

As an ASTM, EN, and JIS certified factory, nearly all manufacturing processes are completed in house, ensuring an excellent quality and offering additional cost benefits. Our aluminum tubing and tubes meet even the strictest customer requirements, and are used in a variety of demanding applications, including SLR (single-lens reflex film camera) lenses, organic photo conductor (OPC), electrolyte battery shell, shock absorber, ski poles and more. Our quality has been proven time and time again, and we are now an upstream material supplier for internationally known companies such as Federal-Mogul, Denso, Canon, Sony, and more.

Our aim is to satisfy your needs in a wide array of applications with a number of aluminum tube options, including customization services if none of our standard products meet your needs. The following guides offer more information about our dimensional ranges.

Outside diameter: 4.8mm-120mm

Min: 4.8mm x 2.0mm x 1.4mm(outside diameter x inside diameter x wall thickness)

Max: 120mm x 100mm x 10mm

Thinnest: 25mm x 24.4mm x 0.3mm

Thickest:120mm x 60mm x 30mm

2. Seamless square tubing

Wall thickness: 16mm-80mm

Min: 10mm*10mm

Max: 90mm*90mm

1. Optical lens: The optical lenses are primarily made using 5052 aluminum alloy or 5056 aluminum alloy, ensuring they have an outstanding turning and oxidation performance.

1. Optical lens: The optical lenses are primarily made using 5052 aluminum alloy or 5056 aluminum alloy, ensuring they have an outstanding turning and oxidation performance.  2. Automobile shock absorbers: These use 6061-T6 aluminum alloy to ensure a high extension rate of up to 20%. 6061-T6 aluminum alloy also meets damping sleeve strength and elongation requirements.

2. Automobile shock absorbers: These use 6061-T6 aluminum alloy to ensure a high extension rate of up to 20%. 6061-T6 aluminum alloy also meets damping sleeve strength and elongation requirements.  3. Electric car battery boxes: These battery boxes are built of 3003 aluminum alloy to avoid cracking of the seamed steel pipe and ensures the battery box features a higher electricity density in the same volume.

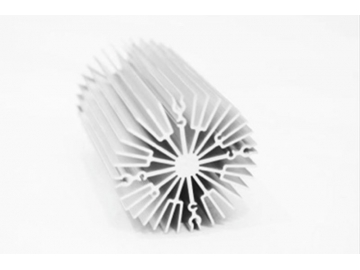

3. Electric car battery boxes: These battery boxes are built of 3003 aluminum alloy to avoid cracking of the seamed steel pipe and ensures the battery box features a higher electricity density in the same volume. 4. Office equipment parts: 6063/6061/3004 aluminum alloy is suitable for manufacturing a variety of office equipment parts, including OPC, heating rollers, and more due to its excellent comprehensive performance.

4. Office equipment parts: 6063/6061/3004 aluminum alloy is suitable for manufacturing a variety of office equipment parts, including OPC, heating rollers, and more due to its excellent comprehensive performance. 5. Sports Equipment: The 7075/7050/7055 aluminum alloy is a popular choice for manufacturing sports equipment like ski poles, trekking poles, bats, and more. The thin wall seamless pipe made of 7075/7050/7055 aluminum alloy features an ultra-high strength, high dimensional accuracy, and capability to withstand cold environments, thus ensuring the sports equipment is lighter and easier to carry.

5. Sports Equipment: The 7075/7050/7055 aluminum alloy is a popular choice for manufacturing sports equipment like ski poles, trekking poles, bats, and more. The thin wall seamless pipe made of 7075/7050/7055 aluminum alloy features an ultra-high strength, high dimensional accuracy, and capability to withstand cold environments, thus ensuring the sports equipment is lighter and easier to carry.  6. Bicycle frames and motorcycle shock absorbers: These are most often made of 7075/7050/7055 aluminum alloy due to the light weight, excellent corrosion resistance, and excellent weldability. 7075/7050/7055 aluminum alloy is widely used in manufacturing three-way parts for the bicycle frame, five-way parts of the bicycle frame, and motorcycle shock absorbers.

6. Bicycle frames and motorcycle shock absorbers: These are most often made of 7075/7050/7055 aluminum alloy due to the light weight, excellent corrosion resistance, and excellent weldability. 7075/7050/7055 aluminum alloy is widely used in manufacturing three-way parts for the bicycle frame, five-way parts of the bicycle frame, and motorcycle shock absorbers.

| Grade | Temper | Application |

| 1070 | H112 | Aluminum foil,capacitor,cable cover,ornament |

| 2011 | T3, T8 | Machined products that require an excellent machinability such as rivets |

| 2014 | T4.T4511 | Parts with high strength and high hardness(including in high temperatures)requirements,such as wheels,truck frames and suspension parts |

| 2014A | T6.T6511 | |

| 2017 | T4 | Electric parts for automobiles,engine management systems |

| 2017A | T4.T4511 | Universal mechanical parts,rivets,traffic and building structural components |

| 2024 | T3, T3511 | Truck wheels,airplane structural components and other structural components |

| 3003 | O | Parts that require a high corrosion resistance or good weldability,such as energy storage system shells for new energy automobiles |

| H112 | ||

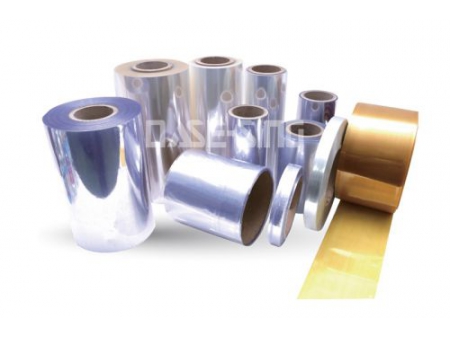

| 3004 | H112, O, H34, H32, H36 | Printer drum, beverage can |

| 3304 | H112, O, H34, H32, H36 | Lamp parts |

| 4032 | F, T6, O | Automotive piston, fixed and moving plates for air conditioners, and heat-resistance parts |

| AHS | ||

| 5052 | H112, H32, H34, O | Camera housing, transportation and ship stamping parts |

| 5056 | ||

| 5083 | H112 | Ship and automobile welding |

| O | ||

| 6005 | T1, T5, T6 | Ladder and television antenna |

| 6101 | T6 | Electric conductor,heat abstractor,high strength bars used in bus |

| 6A02 | T4, T451, T6, T6511, T6510, O, F | Forgings with complicated shapes and airplane engine parts |

| 6061 | T6, T8, O, F | Shock absorber for automobiles,charging connectors for new energy vehicles,high-voltage wire connectors |

| 6063 | T4, T5, T6 | Structural components for automobiles, ships, airplanes and light industry |

| 6066 | O, T4, T42, T6, T62, T6511, T6510 | Welded structural components and forgings |

| 6463 | T4, T5, T6 | Automotive finishing components with a bright surface after anodizing |

| 6013 | T4, T6, O | Baby carriage frames |

| 6020 | T6, T8, O | Engine nozzle parts |

| 6082 | T6 | Automobile suspension arms,automotive instrument panels |

| 7005 | T6 | Car truss, bar, large heat exchanger and sports equipment, such as tennis rackets,baseball bats |

| 7020 | T6 | Aerospace structural components and automobile welding |

| 7050 | T6, T6511, T76, T73, T7351 | Sports equipment including ski poles, baseball bats, alpenstock |

| 7075 | T6, T6511, T76, T73, T7351 | Airplane structural components and other high stress structural components,sports equipment |

Get in touch with us