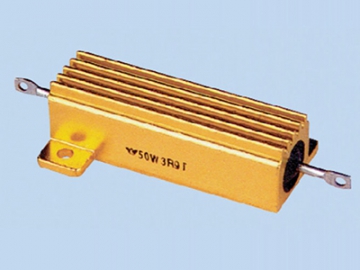

Aluminum Housed Chassis Mounted Wire Wound Resistor

Aluminum housed chassis mounted wire wound resistor is made up of a ceramic resistor and a CuNi-cr or Cr-Ni-wire winding resistor. It is connected to the aluminum housing through a special silicone resin, extremely applicable to operations under harsh conditions.

Dimensions- 5W、75W (A) dimensions drawing

- 75W(B)、100W、150W、200W dimensions

| Type | Power (W) | A ±0.13 | B±0.13 | C±0.25 | D±0.13 | E±0.38 | F±0.39 | L±1.57 | L1±1.57 | L3 | H±0.76 | D1 |

| RX605 | 5 | 11.3 | 12.5 | 1.3 | 2.4 | 16.4 | 8.5 | 28.6 | 15.2 | 8.2 | 1.2 | |

| RX610 | 10 | 14.3 | 15.9 | 2.2 | 2.4 | 20.3 | 10.8 | 35.0 | 19.0 | 10.3 | 2.0 | |

| RX615 | 25 | 18.3 | 19.8 | 2.2 | 3.2 | 27.4 | 13.5 | 49.3 | 27.0 | 13.9 | 2.0 | |

| RX620 | 50 | 39.7 | 21.5 | 2.2 | 3.2 | 28.8 | 15.6 | 70.6 | 50.0 | 15.5 | 2.0 | |

| RX625 | 75A | 39.7 | 21.5 | 2.2 | 3.2 | 28.8 | 15.6 | 93.0 | 72.4 | 15.5 | 2.0 | |

| RX625 | 75B | 93.5 | 66.5 | 17.6 | ||||||||

| RX630 | 100 | 125.0 | 98.0 | 37 | ||||||||

| RX635 | 150 | 162.0 | 135.0 | 55.5 | ||||||||

| RX640 | 200 | 192.0 | 165.0 | 70.5 | ||||||||

| RX645 | 250 | 227.0 | 200.0 | 88 |

| Model | Power (W) | Dielectric Strength (V) | Resistor Range | Maximum Voltage Resistance | |

| Inductive | Non-inductive | ||||

| RX605 | 3(5) | 1000 | 0.1Ω-3.6kΩ | 0.5Ω-1kΩ | |

| RX610 | 10(6) | 1000 | 0.1Ω-6.2kΩ | 0.5Ω-1.5kΩ | |

| RX615 | 25(12.5) | 2000 | 0.1Ω-16kΩ | 0.5Ω-10kΩ | 550V |

| RX620 | 50(20) | 2000 | 0.1Ω-43kΩ | 0.5Ω-20kΩ | 1250V |

| RX625 | 75A(30) | 2000 | 0.1Ω-56kΩ | 0.1Ω-27kΩ | 1900V |

| RX625 | 75B(30) | 2000 | 0.1Ω-56kΩ | 0.1Ω-27kΩ | 1900V |

| RX630 | 100(40) | 2500 | 0.1Ω-75kΩ | 0.1Ω-36kΩ | 1900V |

| RX635 | 150(60) | 2500 | 0.1Ω-100kΩ | 0.5Ω-47kΩ | 1900V |

| RX640 | 200(80) | 2500 | 0.1Ω-150kΩ | 1.0Ω-75kΩ | 2200V |

| RX645 | 250(100) | 2500 | 0.1Ω-180kΩ | 1.5Ω-90kΩ | 2200V |

Derating requirements for high ambient temperature and the installation on cold plate:

Curves A, B, and C are suitable for the operations of non-chassis mounted resistor.

Curve A applies to 605 model and 610 model.

Curve B is suited for 615 model.

Curve C suits 620, 625, 635, 640 and 645 models.

Cold plate size:

605、610 models: 203×203×1 aluminum plate

615model: 231×231×1

520、625、630、635、640 and 645 models: 305×305×3.2 aluminum plate

| Item | Requirement |

| Solder Ability | Surface covered with new solder>95%, △R≤± (1%R 0.05Ω) |

| Terminal Strength | 5W、10W 2.5kg/25W、5kg △R≤±(1%R 0.05Ω) |

| Resistance To Soldering Heat | 275℃ △R≤±(1%R 0.05Ω) |

| Dielectric Strength | ≤10W 1000V, 25W-75W 2000V. 100 W-250 W 2500V △R≤±(1%R 0.05Ω)) |

| Insulation Resistance | >10000MΩ |

| Thermal Shock Resistance | -55℃- 275℃ △R≤±(1%R 0.05Ω) |

| Short-time Overload | 10x rated power, 5s: △R≤±(2%R 0.05Ω) |

| Moisture Resistance | 40℃ △R≤±(2%R 0.05Ω) |

| Load Life | 1000h, 25℃±2℃: △R≤±(5%R 0.05Ω) |

| Shock Resistance | △ R< ± ( 1%R 0.050 ) |

| Vibration | AR< ± ( 1%R 0.050 ) |

| Temperature Coefficient | ±200PPM/℃ |

Order requirements: model, power, resistance, non-inductance, resistance tolerance and code of technical standard should be marked.

Order Example

RX615-25W-100Ω-N-±5%-code of technical standard (not necessary if it is not required)

Resistance tolerance code: F=±1% G=±2% J=±5% K=±10%