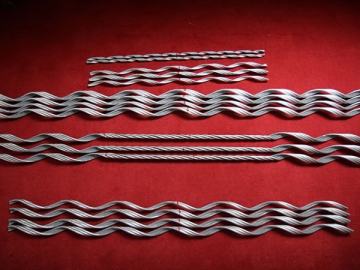

Preformed Splice

Fiber Splice / Splice Rod / Splice Cable

Purpose

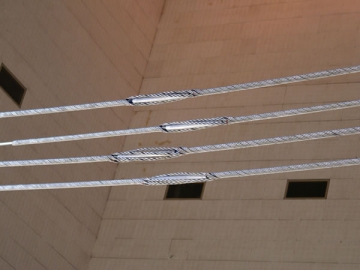

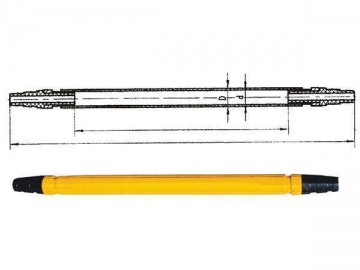

Preformed splice rods include jumper splice rods, full tension splice rods, splice sleeve reinforcing rods, and T type splice rods. The rods connect to aluminum wire, ACSR, steel wire, aluminum clad steel, etc. to achieve the desired mechanical strength and electrical properties.

Features

a. The splice rod's material is the same as the wire to be spliced. It mainly includes aluminum alloy wire, aluminum clad steel, copper clad steel, galvanized steel wire, etc. They possess good corrosion resistance and have ideal mechanical properties and electrical performance.

b. There is a large contact area between splice rods and wire. Stress is uniform. The grip strength can be up to 95%RTS (rated tensile strength) of wire.

c. The resistance between two points in the splice area shouldn't be more than the equivalent length of the spliced resistance.

d. The temperature rise of splice rods at spliced area shall not be more than the temperature rise of the spliced wire.

e. The splice rods are installed easily, without any special tools.

f. Splice rods has good anti-vibration performance and good flexibility. They can protect the cable and extend the system life.

Cautions:

a. According to the conductor, choose the suitable splice rods. Different specifications of splice rods cannot be replaced with each other.

b. We suggest only using one time after the clamp affords full strain.

c. It must be installed by professionally trained staff.

d. Prior to installation, please polish the conductor wire, remove oxide, and then coat with conductive grease.

e. This product is a high-precision device. Make sure to install properly. It should be stored in the packing case to avoid rod deformation resulting from collision and heavy load during transport.

f. When working nearby circuit, be careful to prevent electric shocks.