Small Scale Relocatable Modular Gold Processing Plant

The following situations or difficulties are common in many small gold mines:

(1) Inadequate geological exploration, insufficient amount of proven reserves, narrower or shorter scattered mineral veins which are not suitable for large-scale mining;

(2) Mine owners lack sufficient funds to invest in medium and large-scale mines and have to make profits from small-scale mining and processing;

(3) The access to mines is inconvenient, making it difficult for transportation of large-scale heavy equipment and materials and electric power supply;

(4) Fails to support contiuous operation due to the lack of water resources;

(5) There are artisanal and small-scale miners who use outdated equipment or techniues like spiral chute and amalgamation to recover gold, which is of low efficiency and low recycling ratio and bad for workers' health and thr environment;

(6) After a few months or just one to two years' mining in one are, some mine owners would prefer relocating their plants than re-investing in the same mine;

(7) Small-scale mine owners, in the hope of recovering gold with the best solution, will establish a processing plant as quickly as possible and reduce as many complex yet necessary precedures as possible;

(8) Many small-scale miners expect in local area a small-scale processing plant to which they can sell their raw materials for processing, thus making more profits than using outdated techniques themselves;

(9) Worried about the huge economic loss of building a medium-and-large size processing plant, many mine owners will pilot a small size one for economic evaluation and final decision;

(10) Some previous-processed tailings still contain valuable gold. Miners hoping to minimize their investments and establishing a small-scale processing plant quickly will therefore reduce production cost by recycling gold in such tailings.

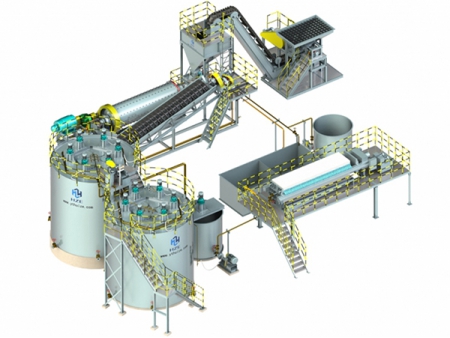

In terms of mining and processing demands of small scale gold mines, we've designed and manufactured small-scale modular gold processing plant which is suitable for recycling gold from rock minerals, quartz minerals, alluvial deposits or tailings via applying gravity separation, floating, cyanidization, or combination of different processing methods. The gold processing plant of a compact structure is favored by more and more mine owners because it provides fine processing schemes, sophisticated techniques, complete functionsand safe and reliable equipment. Besides, it is portable, low-cost, and easy for construction.

- Making the best of mineral resources and ensuring a high recycling rate and economic benefits;

- Advanced technologies and techniques are adopted to completely get rid of mercury and other poisonous chemical substances, thus protecting workers health and environment, reducing labor intensity, and improving production efficiency;

- Lower consumption of energy, water, and raw materials, reduced need of operators, investments and production costs;

- Fast installation, easy reliable operation, maximizing the recovery of gold by the flexible combination of different functional modules.

- Fewer requirements for civil engineering, shortening the project's lead time

- Easy to be containerized, transported, and re-assembled even in the remotest corner of the world.

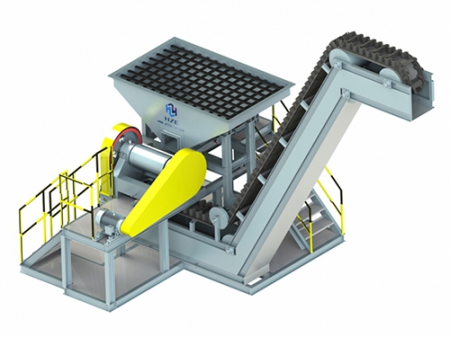

Rocks are crushed to the particle size suitable for grinding and the module consists of composed of hopper, crusher, belt conveyor, ore feeder.

The crushing of ore is usually two-stage. The first crusher can be placed in the mining area (driven by a diesel engine) or the processing plant.

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can dissociate ore into particles suitable for recovery. The module can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone according to customers' needs.

The grinding and classification unit is completely set on a steel frame.

The water supply module is composed of the water tank, water pump and water supply pipeline. This module can fully control the use ratio of water, achieving ideal water balance.

It is composed of the diesel generator, the electrical distribution device and the electrical starter panel, which is suitable for areas that are hard to get to and has difficulties in power supply.

General modules and special modules can be combined flexibly according to different types of minerals to maximize the recovery ration of gold.

The commonly used special modules are gravity separation module, flotation module and cyanidation leaching module.