Ni20Mn6-Ni36 Bimetallic Alloy

Introduction

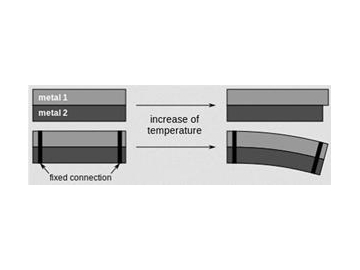

Ni20Mn6-Ni36 bimetallic alloy is made up of two or more layers of alloys or metals with different expansion coefficient that are firmly combined together along the entire contact surface. And it is a thermosensitive composite material whose shape varies with the temperature. The layer with higher expansion coefficient is called active layer, and the other is called passive layer. When resistance bimetallic alloy series are required, which have different resistivity bust almost the same thermal sensitivity, a intermediate layer of different thicknesses can be added between the two layers as a distributary layer to achieve the purpose of controlling different resistivity. The basic characteristic of this bimetallic alloy is that it will bend out of shape with the temperature changes, producing a certain torque. Many devices uses this characteristic to convert the thermal energy to mechanical work so as to achieve automatic control. The bimetal is used as thermosensitive element in control system and measuring instrument.

| Style | Size | ||

| Strip | W= 5~120mm | T= 0.1mm | |

This chart of the bimetallic strip illustrates how the thermal expansion difference of the two metals results in a larger lateral displacement of the strip.

Application

This alloy is mainly used in automatic control equipment and instrument (like exhaust temperature gage, thermostat, pressurizer, temperature relay, automatic protection switching, diaphragm meter) as thermosensitive element like temperature control, temperature compensation, current limiting, temperature indicator, etc.

Composition

High expansion layer: Ni20Mn6

Low expansion layer: Ni36

| Grade | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Bal. |

| Ni20Mn6 | ≤0.05 | 0.15~0.3 | 5.5~6.5 | ≤0.02 | ≤0.02 | 19~21 | - | - | Bal. |

| Density (g/cm3) | 8.1 |

| Resistivity under 20℃(Ωmm2/m) | 0.8±5% |

| Thermal conductivity, λ/ W/(m*℃) | 12 |

| Elasticity modulus, E/ Gpa | 147~177 |

| Specific curvature, K / 10-6℃-1 (20~135℃) | 15 |

| Flexivity, F/ (20~130℃) 10-6℃-1 | 28.5%±5% |

| Allowable operating temperature (℃) | -70~ 350 |

| Linear temperature (℃) | -20~ 180 |

Index

nickel manganese alloy, heat sensitive material, alloy strip