Sheet Mask Cutting, Folding and Bagging Machine

This GM-084Z series machine can cut, fold and bag sheet masks in a variety of specifications, and specifications are easy to change. The production efficiency of the flexible packaging is higher than 98%.

Stable working speed: 100 pieces/min

Rated speed: 120 pieces/min

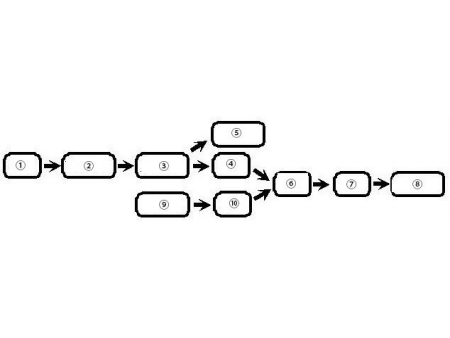

Film rolling, tension controlling, cutting, waste collecting, folding, taking bags from storage, bag opening, bag-in, counting, sending out the finished sheet masks

- ①Film Rolling

- ② Tension Control

- ③ Facial Cutting

- ④ Folding

- ⑤ Waste Collection

- ⑥ Bagging

- ⑦ Counting

- ⑧ Conveying

- ⑨ Taking

- ⑩ Opening

| Production efficiency | ≥98% |

| Operating efficiency | ≥95% |

| Power supply | 380V, 50/60Hz |

| Installed capacity | about 16KW |

| Power consumption at rated speed | about 12KWH |

| Air supply | pressure: ≥0.5Mpa, consumption: <200LPM |

| Noise | Weighted mean ≤85 dB(A) |

- The machine utilizes a bus type servo drive system with a high quality touch screen, ensuring the performance stability and efficiency.

- The bag specification is easily changed using the manual pulse generator adjustment and touch screen specification setting, both of which are easy to operate.

- The facial mask cutter has a sophisticated design and carries out a high - precision processing technology. Patented cutting knife technology triples the service life over traditional knives. It can cut 4,000,000 sheets in one sharpening cycle, and can be re-sharpened anywhere between 10 to 15 times.

- Folding is done neatly, with a folding deviation of ≤±2mm. The sheet mask will not be folded and bagged if the bag is not correctly open. The multi-process automatic detection and elimination system prevents empty bags and defective products.

- The machine features no secondary pollution caused by exposure to food hygiene material in any parts that come into contact with the facial mask. This equipment is also easy to clean.

- This production line will automatically add material without stopping or slowing down, while simultaneously eliminating folded waste. It can work 24h a day with a high production efficiency. It can also automatically remove the front end of added materials and any abnormally folded sheet masks.

Gachn is a reliable facial sheet mask production line manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment. There are wide range of plastic bag packaging machines for packing disposable sanitary and non-woven facial mask products. Gachn is a joint stock company contributed to providing quality disposable facial sheet mask machines and custom packaging solutions for customers.

Gachn is a professional counting stacking sanitary pad machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment.