Flange Yoke Automotive Forgings

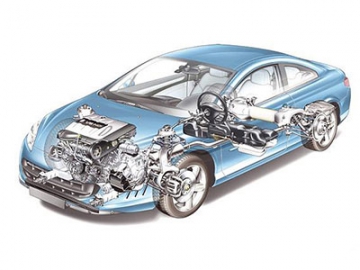

Solution: For connecting the transmission and drive the axle

Material: Carbon steel SAE1035, SAE1045, CM490

Precision: ±0.01mm

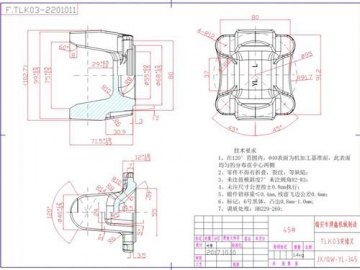

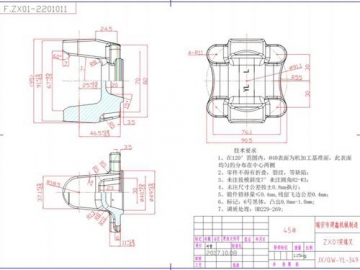

Product drawingProcessing

1. Our R&D personnel are responsible for the development of new products according to customer needs, as well as the development and customization of various mechanical components

2. Mold processing: CAD design, CAM, UG, SOLIDWORKS modeling, CNC processing.

The molds are made of a special die steel, which has excellent performance in precision, fatigue resistance and wear resistance, ensuring customers receive reliable, high quality products.

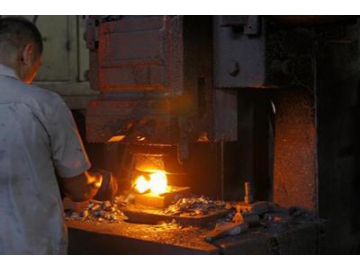

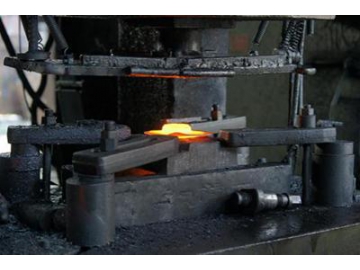

3. After a series of processes covering heating, open die forging, preforming, trimming, and correction, a semi-finished forging is achieved, followed by a final product developed through a heating and machining performance.

Open die forging

It uses a friction welding machine for production, during which the basic geometric shape of the forged product is achieved, and the internal structure (mechanical performance) is improved after a hammering process

Sheet stamping

Uses the metal blanks to achieve the basic product shape according to design requirements

Die cutting

Cutting the burr on the semi-finished product

Rectification

Rectification uses a height Vernier caliper to determine that the processed ends are the correct size, with a measuring precision of 0.02mm. Necessary testing equipment includes the following: Coordinate measuring machine, Vernier caliper, outside micrometer, circular tester and more.