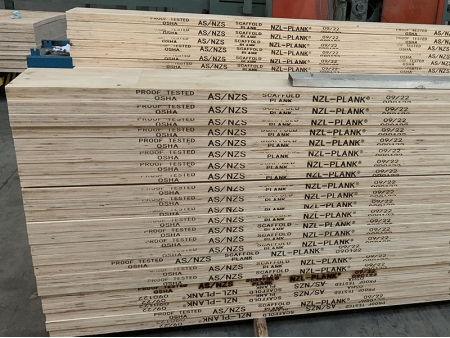

LVL Plywood (Laminated Veneer Lumber)

Laminated Veneer Lumber (LVL), also known as LVL plywood, is made by layering thick wood veneers in the same grain direction and bonding them under high heat and pressure. The material is then cut to the required dimensions, ensuring precision and strength.

LVL plywood is highly valued for structural applications, offering superior strength and stability with minimal waste. Its ability to overcome natural wood defects and adapt to various sizes makes it an ideal solution for projects where durability and precision are essential.

-

- Material: Poplar, Pine, etc.

- Size: 225×3900mm/6000mm, 230×3900mm/6000mm, 235×3900mm/6000mm, and can be upon request

- Thickness: 5mm-300mm

- Density: 530-650kg/m³

- Glue: WBP-PHENOLIC, WBP-MELAMINE, MR

- Formaldehyde Emission: E0, E1, E2

This plywood is characterized by its uniform structure, high strength, and excellent dimensional stability, making it suitable for various applications, including:

- Core material or frame for high-end furniture surfaces.

- Framework for doors and windows, internal wall supports, window frames, and stairs.

- Construction components such as building beams, roof trusses, I-beams, and structural frameworks for residential roofing.

- Materials for vehicles, ships, and railway sleepers.

LVL plywood disperses and offsets natural defects such as knots and cracks, minimizing their impact on the material’s strength. This results in uniform strength, stability, and reduced material variability, making it an ideal alternative to solid wood for structural applications.

LVL offers flexible sizing options, as it is not constrained by the shape or defects of raw logs. Panels can be custom-cut to any dimension, with lengths up to 8 meters and thicknesses up to 300mm, maximizing efficiency and material usage. This versatility allows LVL plywood to achieve 100% raw material utilization, making it a sustainable and efficient choice for construction and manufacturing projects.

- Veneer Cleaning

- Veneer Drying

- Gluing and Grouping

- Pre-pressing

- Cutting & Sanding

- Inspection & Storing

- Packaging