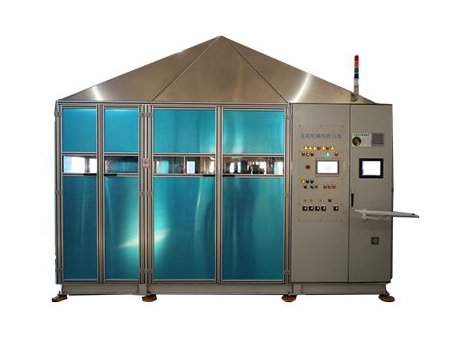

Automatic Rotary Seals Moulding Machine

Request a Quote

Complete rubber production line combining extrusion and vulcanization

Our automatic rotary seals moulding machine seamlessly combines extrusion and vulcanization, delivering high precision and efficiency in creating high-quality rubber products. This rubber seal production line consists of main structure, feeding unit, rubber extruder, vulcanization system, rubber extrusion cutting machine, appearance inspection system, packaging machine, electrical cabinet, industrial protection guards, control panel, hydraulic pump, etc.

Specifications

| Mold Temperature | 20℃-350℃ |

| Holding Pressure | 1500kgf |

| Finished Rotary Seal Diameter | 27-60mm |

| Materials | metal structure, rubber strip with cross section of 12mm, mold release agent |

| Capacity of Seals Collection Unit | 400pcs×18=7200pcs |

| Metal Structure Loading Capacity | 250pcs×24=6000pcs |

| Rubber Loading Capacity | one bucket |

| Production Cycle | 2.5s-5s |

| Vulcanization Time | 10s-60s |

| Main Motor Power | 0.75 kW |

| Speed Control | AC VFD speed regulation |

| Heating Power | 300w×16 1.2 kW 200w×4 (8st), 300w×24 1.2 kW 200w×4 (12st) |

| Dimensions (L*W*H) | 3800*2100*2200mm |

| Production capacity | 720-1440 pcs/hr |

Features

- High-Speed Vulcanization

The moulding machine features a rotary indexer for the vulcanization process, offering up to 8 or 12 workstations, AC motor-driven, and variable frequency speed control, achieving a rapid rotation cycle as short as 2.5 seconds. - Efficient Locking Mechanism

The locking mechanism employs hydraulic cylinders supported by disc springs and locking blocks, providing a locking force of 2.5 tons. This simple and maintenance-friendly design ensures reliable operation. - Advanced Control System

The machine's PLC control system ensures safety, reliability, and simple debugging. - Precise Heating Control

The heating components and molds are equipped with an automatic temperature display. The heating temperature can be controlled within ±0.5°C, offering precise temperature control for different processing requirements. - Piston-Style Extrusion

The rubber extrusion section utilizes a piston-based structure, complemented by automatic feeding functionality. This secure and reliable design ensures seamless bonding between rubber and metal structure, eliminating detachment issues. - Automated Feeding

The automatic feeding system efficiently places metal structure and bonded rubber into molds, achieving automated and reliable feeding, removing the need for manual intervention. - Seamless Product Removal

The product removal and cutting section efficiently extracts vulcanized products from molds and trims excess edges, ensuring finished products without the need for secondary processing. - Automatic Visual Inspection

The product's appearance inspection section features an intelligent visual system that examines aspects such as appearance, color, integrity, inner and outer dimensions, eliminating defective items and ensuring high production standards. - Streamlined Packaging

The automated packaging section arranges qualified products in an orderly manner, simplifying storage and packaging operations. - Advanced Aluminum Frame

The machine's aluminum frame encapsulates the production process, enabling a true unmanned production environment for enhanced efficiency and quality.