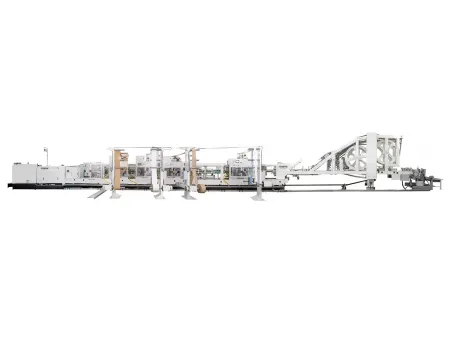

Building Material Paper Bag Production Line

Multi-wall paper bag making machine for cement bags, gypsum bags, dry mortar bags and wall putty bags

This building material paper bag production line consists of the YD-5860 tuber machine and the YD-2018-18 bottomer machine, designed for producing valve bags for cement, dry mortar, gypsum powder, wall putty, and more. The building materials are fed from the top or bottom valve, and after filling the material, the bags automatically form into a rectangular shape. These valve bags are known for their strength, reliability, easy transport, and aesthetic appeal.

Additionally, we offer customized equipment based on your production volume needs, providing machines with matching speeds to better meet customer requirements. We also offer complete factory solutions, including auxiliary equipment such as overhead cranes, forklifts, and hydraulic balers.

Boost your production efficiency with tailored solutions.

Contact us today to learn how the building material paper bag production line can meet your packaging needs.

Tuber Machine YD-5860

- Max. speed: 450 tubes/min

- Tube width: 300-600mm

- Tube length: 410-1250mm

Bottomer Machine YD-2018-18

- Max. speed: 200 bags/min

- Bottom width: 90-170mm

- Bag width: 300-600mm

- Bag length: 350-1300mm

- Center distance: 260-1000mm

- First valve sheet length (optional): 90-270mm

- Second valve sheet length (optional): 90-270mm

- Internal reinforcement patch length (optional): 200-350mm

- External reinforcement patch length (optional): 250-400mm

- High-Quality Components

Core components of the equipment are sourced from well-known brands in Germany, Italy, and other countries. - High Production Speed

The production speed can reach up to 450 bags/min, efficiently meeting production demands while reducing labor costs.

- Ultrasonic sealed valve bag for filling wall putty powder

- PE valve bag for filling tile adhesive powder

- Self-closing valve bag for filling aggregate

- Self-closing micro-perforated bag for filling cement