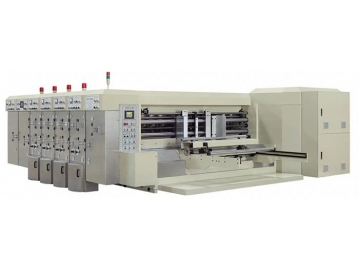

G4 Corrugated Board Converting Machine

(G4 High Speed Printer Slotter Die Cutter)

G4 Corrugated Board Converting Machine is composed by 4 parts, which is the sheet feeder, the corrguated box printer, the corrguated box slotter and the die cutter.

The product can complete multi-color cardboard printing, cutting, pressure lines, trimming, slotting, cutting angle, die cutting, drilling and other multi-channel processes in one time.

The sheet feeder uses the servo drive and the feed roller rotates to transfer the cardboard to the corrguated box printer for printing. After the cardboard reaches the corrguated box printer, the net roller and the rubber roller transfer the ink to the printing plate on the printing roller and the cardboard is transferred stably by the sheet feed shaft, then the pattern is accurately printed on the cardboard. Afterwards, the cardboard is transfered to the slotter for slotting or the die cutter for die cutting to meet the customers's requirements in the shape of the carton.

- The corrugated box making machine, the fan and vacuum use variable frequency control to control the air volume, which can be adjusted according to different speed.

- All units can be reset to zero.

- All units are controlled by computer and have the memory function, which can remember 999 orders.

- The corrugated box making machine has ink lacking alarming device and when it lacks ink it will stop feeding, which can prevent damage to the machine due to the lack of ink while high speed running.

- The gap between up and low wheel shafts is adjusted by self-locking and all the units adopt flat oil separation device.

- Fault alarming accurately and high strength of the safe production.

| Model | JF0820 | JF0920 | JF1224 | JF1424 | JF1228 | JF1428 | JF1628 | JF1632 | JF2236 |

| Max Speed (pcs/min) | 250 | 250 | 200 | 200 | 180 | 160 | 160 | 150 | 110 |

| Max feeding size (mm) | 800×2050 | 900×2100 | 1200×2500 | 1400×2500 | 1200×2900 | 1400×2900 | 1600×2900 | 1600×3300 | 2200×3700 |

| Min feeding size (mm) | 260×600 | 280×600 | 370×700 | 370×700 | 370×700 | 390×700 | 450×850 | 450×850 | 650×800 |

| skip feeding size (mm) | 1200×2050 | 1200×2050 | 1600×2500 | 1600×2500 | 1600×2900 | 1600×2950 | 2000×2850 | 2000×3200 | 2400×3200 |

| Max print size (mm) | 750×2000 | 850×2000 | 1150×2400 | 1350×2400 | 1150×2800 | 1350×2800 | 1550×2800 | 1550×3200 | 2150×3600 |

| Min slotting gap (reverse knife) | 230×70×230×70 | 230×70×230×70 | 240×70×240×70 | 250×90×250×90 | 240×70×240×70 | 250×90×250×90 | 280×120×280×120 | 280×120×280×120 | 280×120×280×120 |

| Printing plate thickness (mm) | 7.2 | ||||||||

| Board thickness | 1.5-12 | ||||||||

Jiufeng company as a full experienced corrugated carton making equipment manufacturer, we provide complete corrugated cardboard box machine line, including corrugated cardboard printer, cardboard slotter cutter, cardboard folder and gluer. The corrugated cardboard machines we made with plenty of experience since 1996, we are sure to offer customers high quality corrugated carton equipment and corrugated cardboard solutions for customers.