High Electrical Conductivity Super-elastic Alloy

Introduction

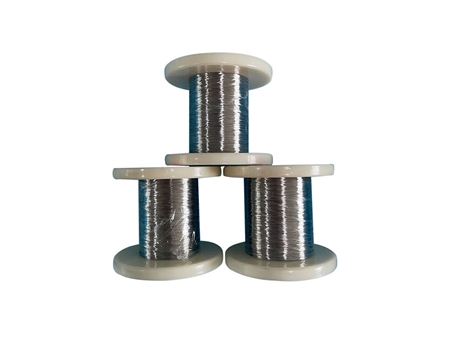

OHMALLOY provided high electrical conductivity super-elastic alloys include 3J31, 3J32 and Co67NiNb.

Co67NiNb alloy does not contain beryllium, which avoid the beryllium harm during the production, and it is the substitute of 3J31 and 3J32 alloys.

3J31 and 3J32 alloys is a high electrical conductivity super-elastic alloy of nickel-based precipitation strengthened, which contain beryllium. 3J31 alloy can work below 350℃. 3J32 is based on the 3J31, adding with about 0.5% titanium alloy. It has features of higher strength, elongation after fracture, fatigue limit, heat resistance and corrosion resistance. The changes of strength and fatigue limit are small within the temperature range of -200-472℃.

Co67NiNb is cobalt based precipitation strengthening alloy of high electrical conductivity and super-elastic. They have good plasticity and are easy to be processed under solid solution condition. Co67NiNb alloy even can work at 400~450℃. With solid solution or aging treatment after cold strain, the high mechanical property, elastic property and electrical conductivity are obtained by precipitation strengthening. This series alloys have features of high elasticity modulus, strength and fatigue limit, low resistivity, excellent oxidation resistance and corrosion resistance, good heat resistance, etc. Its electrical conductivity is lower than that of beryllium-bronze, but the operating temperature and fatigue resistance are better than the latter.

Chemical composition (%)| Grade | C | Mn | Si | P | S | Al | Cu | Fe | Be | Ti | Ni | Nb | B | Co |

| 3J31 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.01 | ≤0.020 | ≤0.10 | ≤0.10 | ≤0.30 | 1.9~2.2 | -- | Balance | -- | -- | -- |

| 3J32 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.01 | ≤0.010 | ≤0.10 | ≤0.10 | ≤0.30 | 1.9~2.2 | 0.4~0.6 | Balance | -- | -- | -- |

| Co67NiNb | ≤0.05 | 0.10~0.30 | 0.10~0.30 | ≤0.01 | ≤0.010 | -- | -- | -- | -- | ~0.03 | 27.0~29.0 | 4.8~5.20 | ~0.003 | Balance |

| Grade | Heat treatment process |

| 3J31 | Preserve heat for 10-60minu at 1000~1040℃, then conduct water quenching 1~2h aging treatment at 500~520℃; cooling in air Preserve heat for 10-60minu at 1000~1040℃, then conduct water quenching 3-6h aging treatment at 470~490℃; cooling in air 70% cold strain 2-3h aging treatment at 470~490℃, cooling in air |

| 3J32 | Preserve heat for 10-60minu at 1020~1050℃, then conduct water quenching 2-3h aging treatment at 500~520℃; cooling in air 70% cold strain 2-3h aging treatment at 480~500℃; cooling in air |

| Co67NiNb | water quenching at 1000℃ 30%~40% cold strain 1h aging treatment at 600~650℃; cooling in air water quenching at 1000℃ 4-6h aging treatment at 620~670℃; cooling in air |

Note: aging temperature after the solid solution of 3J31, 3J32 increased to 350℃, when the high electrical conductivity was taken as the main index.

Index

heat resistant alloy, cobalt alloy