PE Pipes and Fittings (Outdoor Use)

The PE pipes and fittings are designed to give a safe and reliable solution for outdoor gas transmission. Polyethylene gas piping systems are specifically engineered for the underground environment. Kingbull offers premium quality polyethylene pipes and fittings that assemble in minutes to form a complete underground gas piping system.

Applications:

PE pipes and fittings are widely used in natural gas, coal gas and LPG pipe networks and other fields.

-

PE Gas Pipe -

PE Gas Pipe, PE320 -

PE Gas Pipe for Coal Mine, PE160 and PE100 -

PE Gas Pipe for Coal Mine, Large Diameter -

PE Gas Pipe for Coal Mine, PE 100 -

PE Gas Pipe for Coal Mine, PE 100 -

PE Gas Pipe for Coal Mine, PE 160

Features of PE Pipes and Fittings

1. High strength

2. Excellent resistance to environmental stress cracking

3. Great creep resistance

4. Good toughness and flexibility, with high adaptability

5. Remarkable resistance to corrosion resistance, high longevity

6. Smooth inner surface, ensuring small flow resistance, large flow capacity, and large cost savings in construction

7. Perfect anti-wear and low temperature impact resistance performance

Specifications of Underground PE Pipes

PE Pipe Fittings-

V-Shaped Elbow with Flanges -

Tee with Flanges -

Electro-welded Equal Tee, T63 -

Electro-welded

Socket, S63 -

Reducing Socket, S63×32 -

45° Elbow, L90 -

End Cap, D63 -

Reducing Socket, S110×63 -

Steel-Plastic Coupling, 63/50 -

Male Coupling, 63 -

Male Coupling, 63 -

Steel-Plastic Coupling -

Bypass Bend, 25 -

90° Elbow, SDR11 -

Ball Valve with Single Discharge Pipe -

Female Elbow, 50 -

45° Reducing Tee Large Tee -

Equal Tee, 63 -

Tee for Floor Heating Pipe -

End Cap, 63

-

Metal Flange, 63 -

Double Union, 32 -

32 Double Union Ball Valve, 32

Advantages of Kingbull PE Pipes and Fittings

1. Quality Raw MaterialsWe use imported PE80, PE100 and other grade polyethylene as raw materials. Advantages of the materials include:

a. High compressive strength;

b. Great performance in resisting slow growth of stress cracking and rapid stress propagation;

c. Excellent machinability

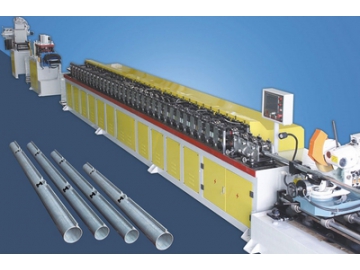

2. Advanced Equipment

a. Original Battenfeld equipment, with high production stability;

b. KIV forced feed system;

c. BM barrier screw;

d. Online test at any time to ensure uniform wall thickness;

e. State of the art test equipment

3. Modern Production Process

Materials mixing and feeding—Extruding—Vacuum sizing—Cooling—Jet printing—Pulling—Cutting—Packing —Finished products storing

4. Supporting System Advantages

a. Partner with the largest electro welded fittings producer, ensuring product quality and integrity of our supporting system;

b. Pipes and fittings are made of the same quality materials;

c. Heat welding to ensure reliable product quality, with complete heat welding tools;

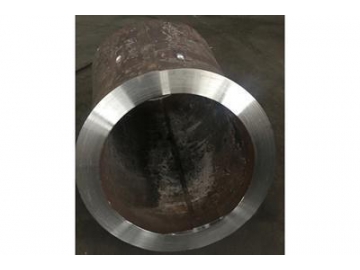

d. Kingbull butt welding machine is suitable for welding pipes with a diameters of more than 110mm.